2025 is a big year for consumer 3D printing.

For the first time, multi-material and multi-color FDM printing moved from “high-end features” to tools that everyday makers can use. Many brands launched new systems. Many of them focus on faster switching, cleaner prints, and less wasted filament.

The change did not happen by chance.

Companies have been working on this for years. But in 2025, everything lined up. New heating methods became stable. Toolheads became smarter and lighter. And users began asking for richer models with more colors and materials.

During Formnext 2025 in Germany, we saw this shift up close. After speaking with many exhibitors, one thing became clear:

multi-material FDM is no longer a niche feature. It is becoming the new normal.

Big brands like Bambu Lab, Prusa, Creality, Snapmaker, Elegoo, and Anycubic all brought new ideas. Together, they cover almost all of the global consumer FDM market. When all of them move in the same direction, the whole industry changes with them.

2025 is that turning point.

Why Multi-Material FDM Exploded in 2025

Multi-material printing has been around for a long time, but it was often slow, hard to set up, and wasted a lot of filament.

In 2025, this changed. Several key ideas came together at the same time, making the technology easier and more practical for normal users.

1. Faster Heating and Smarter Toolheads

Old toolheads took a long time to heat up or cool down. This made switching between materials slow and painful.

In 2025, many companies moved to induction heating and pre-heated modules. These systems warm up very fast—often in just a few seconds. Toolheads also became lighter and easier for the printer to move.

What this means for users:

- less waiting

- fewer errors

- smoother color changes

- better print quality

2. Much Less Material Waste

Before this year, most multi-color printers used purge towers. This means the printer had to push out old filament every time it switched colors. The waste was huge.

Now, many brands use new designs that switch materials with almost no purging.

Some swap full hotend modules. Some use a single nozzle with internal selectors. Some let filament stay inside the print head so less flushing is needed.

3. Users Want More Color and More Materials

People no longer want only simple, single-color prints. Makers want models with:

- bright colors

- mixed textures

- flexible and hard parts together

- stronger support materials like PVA

Because of this demand, companies now focus on making multi-material printing simple enough for beginners and powerful enough for prosumers.

4. Big Brands Enter the Same Race

In 2025, almost every major FDM brand launched or teased a new multi-material system. When all leading companies invest in the same direction, progress becomes very fast.

This also means more choices for users:

- more price ranges

- more printing methods

- more systems designed for real-life use

It is rare for the industry to move so quickly at the same time. But this year, the shift is clear and strong.

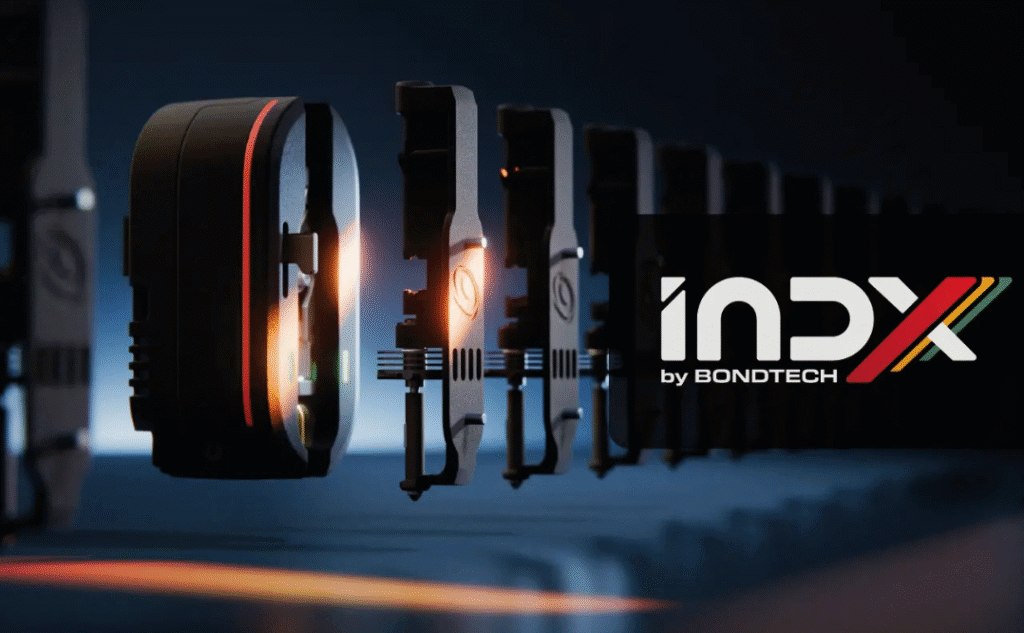

Prusa × Bondtech INDX (8-Tool Switching System)

What It Is

The INDX system is a new multi-material upgrade made by Prusa and Bondtech together. It is designed for the upcoming Prusa CORE One printer.

Instead of having many full toolheads, it uses one smart head and several lightweight passive tools. Each passive tool holds only the nozzle and the filament path, making the system simple and light.

This design helps the printer switch tools quickly without adding too much weight.

How It Works

The INDX system uses induction heating. This is a method that warms metal very fast without touching it. With this technology, each nozzle can heat in about 12 seconds.

This makes tool changes feel almost instant.

Another smart feature is its auto-adjusting extruder. It can handle many material types, from hard plastics to soft TPU, without needing manual tuning. The system adjusts itself and keeps the flow stable.

Key Numbers

- 8 total tools

- ~12 seconds to heat a cold nozzle

- supports flexible and rigid materials

- designed as an upgrade module for Prusa CORE One

- release planned for 2026

These numbers show that Prusa is moving strongly toward a faster, cleaner multi-material workflow.

Why It Matters for You

This system makes multi-material printing easier for normal users. You get:

- fast tool changes

- less wasted filament

- better color control

- smoother prints

- more freedom to mix materials

It also removes many of the old pain points, like slow heating and heavy toolheads. For anyone who wants clean, multi-color or multi-material prints, INDX is a big step forward.

Bambu Lab H2C with Vortek Switching

What It Is

The Bambu Lab H2C is a new printer concept that uses Bambu’s Vortek hotend switching system.

Instead of pushing old filament out of a single nozzle, the H2C swaps the entire hotend module. Each module already has its own nozzle and heater built in. This lets the printer switch materials without long flushing steps.

It is a simple idea, but very powerful. By changing the whole hotend, the printer avoids mixing colors and keeps prints clean.

How It Works

Each hotend module is pre-heated using induction heating. This lets it reach printing temperature in about 8 seconds.

When it is time to switch colors or materials, the printer removes one module and snaps in another. The process is fast and does not require wires, because the system is fully wireless.

Since the printer is not flushing old material through a nozzle, it produces almost no purge waste. This is one of the biggest improvements over older multi-material systems.

Key Numbers

- 8 seconds to reach full heat

- almost zero purge waste

- wireless module design

- clean switching between colors and materials

These numbers show why the H2C is attracting so much attention.

Why It Matters for You

The H2C makes multi-material printing:

- faster (no long waiting times)

- cleaner (no big purge blocks)

- easier (no tuning between materials)

- more reliable (no leftover color in the nozzle)

You get sharp color lines, less stringing, and better surface quality—even when mixing several materials. This can help beginners and prosumers print models that look more professional with less effort.

No products found.

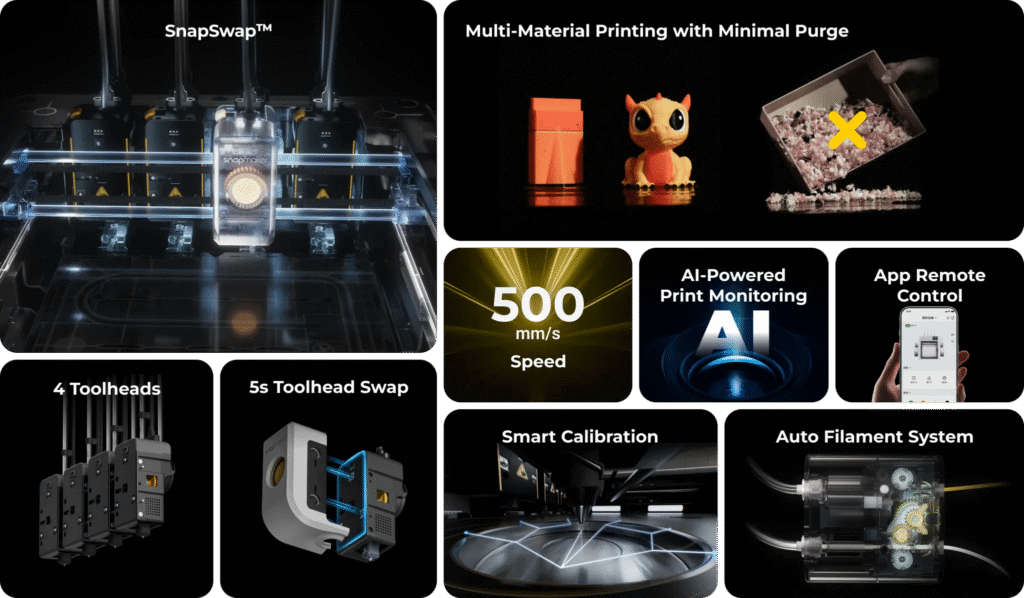

Snapmaker U1 (Four Independent Heads)

What It Is

The Snapmaker U1 is a new multi-material printer that uses the company’s SnapSwap toolhead system.

It holds four independent print heads, and each one can be pre-heated before the printing starts. This means the printer does not need to warm up a cold nozzle every time it switches colors.

The design makes the U1 feel fast and smooth, even when printing complex, colorful models.

How It Works

Each of the four heads has its own heater, filament path, and nozzle.

Because the heads are always ready, the printer can switch from one to another in about 5 seconds. This is much faster than older systems that needed long flushing steps.

Since each color or material has its own head, the printer does not need to push old material out of the nozzle. This greatly reduces purge waste.

Snapmaker says this system can cut waste by up to 80%, which also saves money and keeps prints cleaner.

The U1 supports many materials, including PLA, TPU, and ABS, giving users more creative options.

Key Numbers

- 4 independent toolheads

- 5-second switching

- up to 80% less material waste

- supports PLA, TPU, ABS, and more

These numbers show how the U1 brings real speed and flexibility to multi-material printing.

Why It Matters for You

The Snapmaker U1 is helpful for users who want:

- fast and simple color changes

- much less filament waste

- strong results when mixing materials

- reliable switching without leftover colors

- sharper details in multi-color prints

With its four ready-to-use heads, the U1 removes many old problems from multi-material FDM and makes the workflow easier for beginners and prosumers alike.

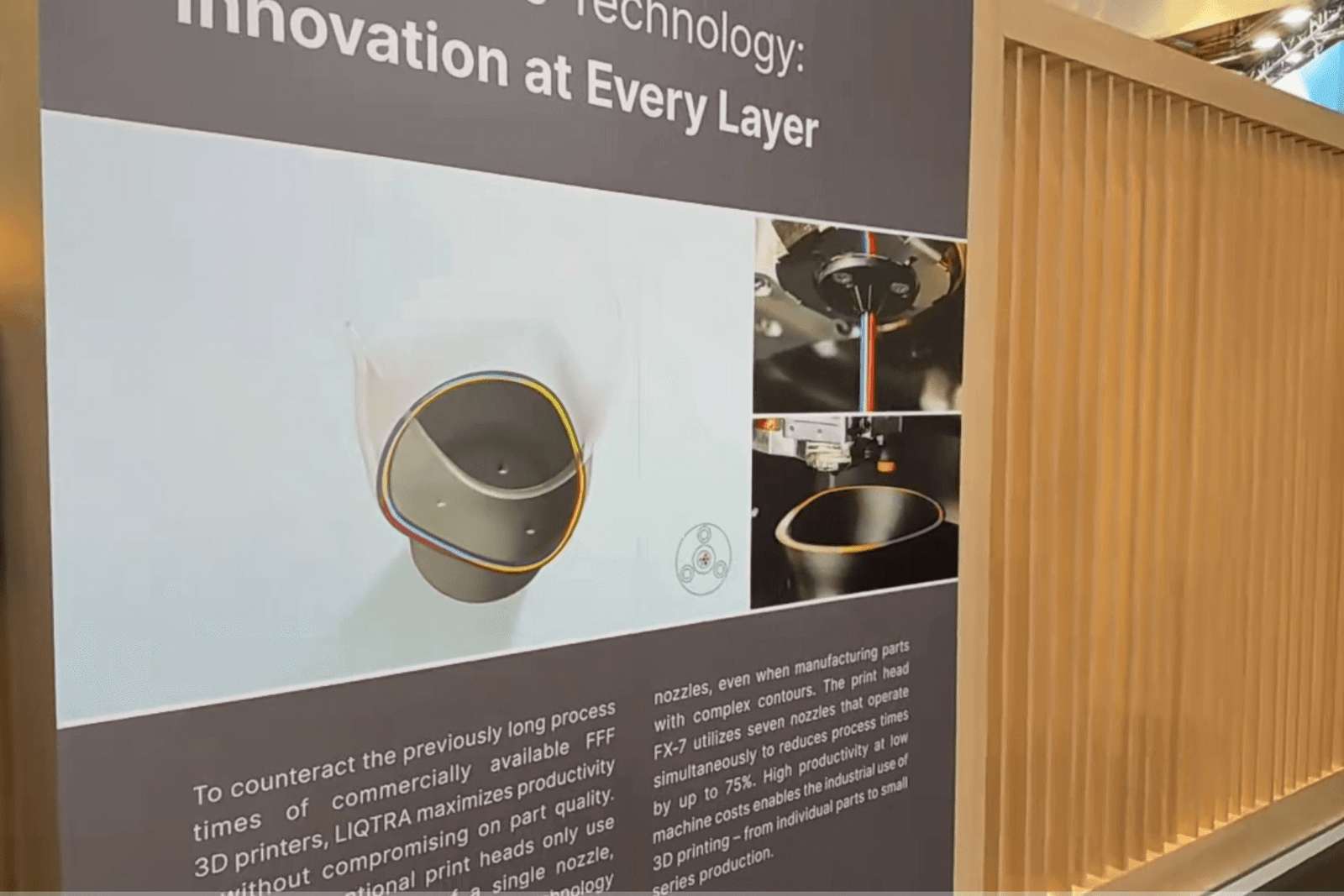

LIQTRA FX-7 (Zero-Waste “Seven-in-One” Nozzle)

What It Is

The LIQTRA FX-7 takes a very different approach to multi-material printing.

Instead of swapping toolheads, the FX-7 feeds seven different materials into one single nozzle. Inside the nozzle is a small rotating part that selects which material to use.

This means the printer can change colors or materials without removing anything or flushing the nozzle.

How It Works

The heart of the system is its rotating selector. When the printer needs a new color or material, the selector simply turns to a new channel.

Because of this design, the printer does not need to purge old material. The system switches cleanly, fast, and with no waste.

The FX-7 can even switch materials layer by layer, giving users very fine control over color changes. This makes it good for gradient prints, mixed materials, or detailed artwork.

Key Numbers

- 7 materials feeding one nozzle

- zero purge waste

- instant switching

- supports smooth color transitions

- about 75% faster than older purge-based systems

These numbers make the FX-7 one of the most efficient multi-material setups shown at Formnext 2025.

Why It Matters for You

The FX-7 is powerful for users who want:

- no wasted filament

- smooth color blends or gradients

- fast changes between materials

- high quality on detailed prints

- clean results without leftover color

For artists, designers, and professional makers, this system can open creative options that older multi-material printers could not manage well.

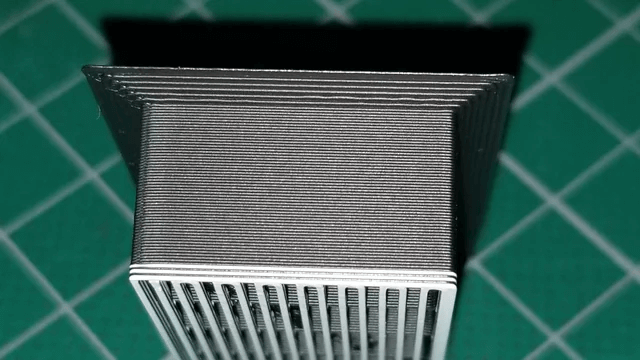

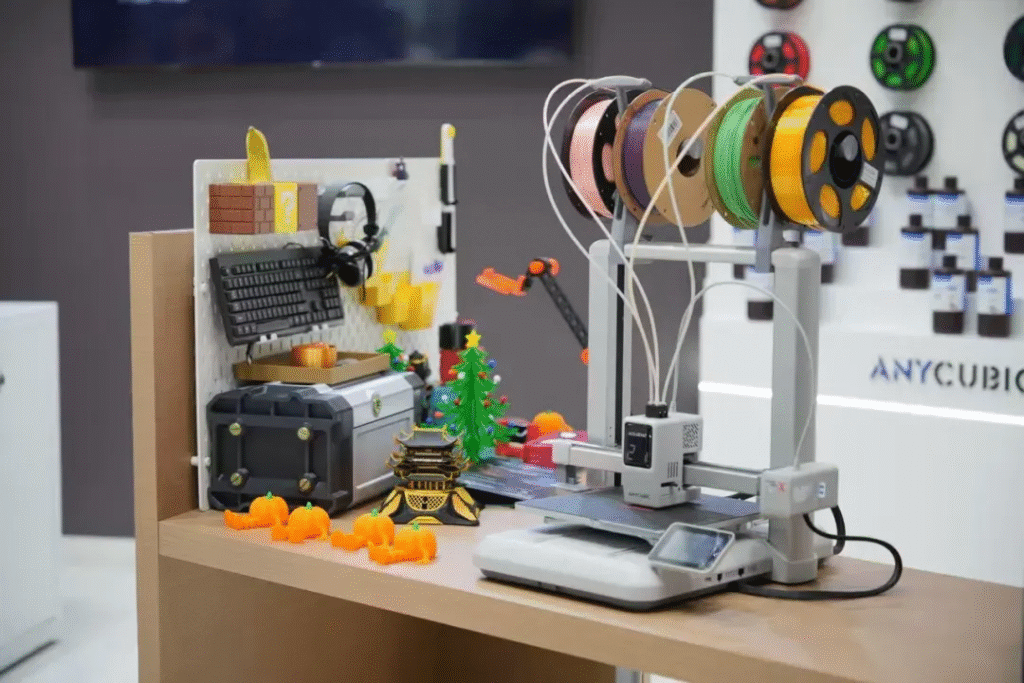

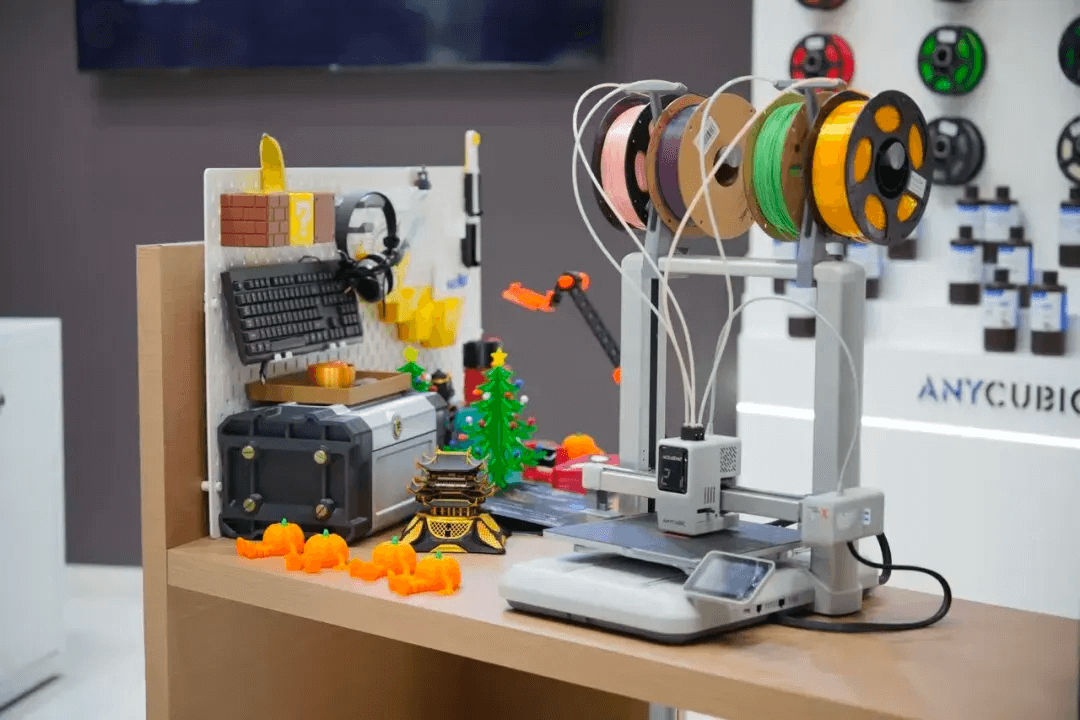

Anycubic KobraX (Fast Switching With Minimal Purge)

What It Is

The Anycubic KobraX is a new multi-material FDM printer designed for faster switching and cleaner prints.

Unlike older systems, the KobraX keeps the filament inside the print head instead of pulling it all the way back to the spool. This small change makes the whole switching process much quicker.

The printer also uses a new compact hotend, which helps reduce the travel distance during material changes.

How It Works

Because the filament stays close to the nozzle, the printer does not need to move it very far when switching colors.

The hotend has a lower cutter position, so it trims the filament earlier, reducing the amount of old material left in the nozzle.

With less material to clear, the KobraX produces much less purge waste and switches faster than many older multi-material systems.

Tests show that printing a four-color model can save 40–50% of both time and filament.

The KobraX also works with a wide range of materials, including PLA, TPU, and PVA for dissolvable supports.

Key Numbers

- 40–50% savings in time and filament on multi-color prints

- shorter filament travel path

- supports PLA, TPU, PVA, and more

- reduced purge waste due to new cutter + hotend design

These numbers show how Anycubic is trying to make multi-material printing faster and more affordable.

Why It Matters for You

The KobraX is helpful if you want:

- quicker color changes

- less wasted filament

- easier support removal (with PVA)

- stable mixing of rigid and flexible materials

- good performance without complex setup

Its new switching system makes multi-material printing more friendly for beginners while still useful for advanced users who need clean results.

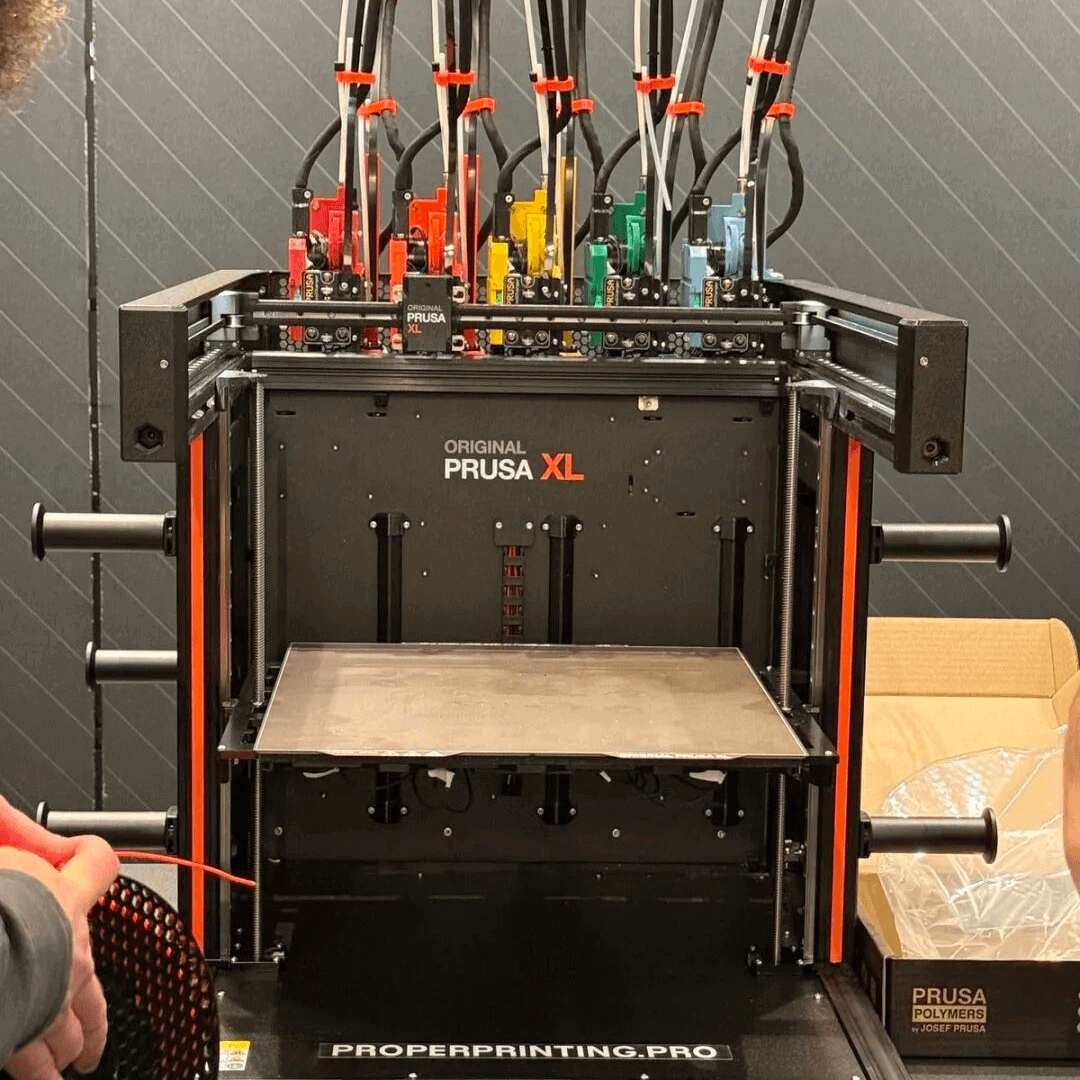

Prusa Five-Head Concept (Large-Format Multi-Material)

What It Is

Besides the INDX system, Prusa also showed a new five-head multi-material concept.

This design looks more like an industrial machine.

It is built for users who need bigger prints and stronger performance. The system can switch between five different toolheads while printing one large part.

It is still a concept, but it gives a clear picture of where Prusa wants to go in the next few years.

How It Works

Each of the five toolheads has its own nozzle and material path. When the printer needs to change materials, it moves the active head away and brings a new one into place.

The switching process is fast and smooth because the machine is built with a rigid frame and high-speed motion system.

The concept also supports high-speed FDM, which means it can move and print faster than older Prusa models.

With a build area close to 300 mm, the machine can create larger objects that mix soft and hard materials in one print—such as wheels, grips, or flexible joints.

Key Numbers

- 5 independent toolheads

- ~300 mm build size

- supports high-speed FDM

- built for complex, mixed-material parts

These numbers show that Prusa is expanding beyond hobby printing and stepping into prosumer and light-industrial territory.

Why It Matters for You

This concept is useful for users who want:

- large prints with many materials

- strong and flexible parts in one print

- fast switching between colors

- better reliability on complex jobs

If Prusa turns this concept into a real product, it could become a powerful option for makers who need both size and multi-material performance.

Other Multi-Head Systems Seen at Formnext

At Formnext 2025, we also saw new multi-material ideas from ELEGOO, Creality, and Flashforge. Each brand showed a different way to solve the same problem: how to switch materials faster and with less waste.

These systems were still early-stage, but they help show how quickly the industry is moving.

ELEGOO

ELEGOO displayed its own multi-head concept designed for clean color switching.

The system focuses on:

- simple setup

- easy material paths

- smoother changes between colors

While not as advanced as some of the high-end systems, ELEGOO’s approach aims to make multi-color printing affordable for more users.

Creality

Creality showed a new multi-material prototype that gives the printer:

- better control during switching

- cleaner filament paths

- more stable performance at high speed

Creality’s goal seems clear: bring multi-material features to a wider user base without making the setup too complex.

Flashforge

Flashforge also demonstrated a multi-head printer designed for practical use.

Its system focuses on:

- steady switching

- strong reliability

- support for many common materials

Flashforge is known for stable machines, and this new design continues that direction.

Why These Systems Matter

Seeing ELEGOO, Creality, and Flashforge all entering the multi-material space confirms one big trend:

Almost every major FDM brand is now building a multi-material system.

This means:

- more choices for users

- better prices

- faster updates

- stronger progress across the whole market

And when many brands compete in the same space, the technology improves very quickly.

What This Means for the Consumer Market in 2025

The rise of multi-material systems in 2025 is more than a list of new machines.

It marks a real change in how people will use FDM printers at home and in small studios.

Here are the biggest shifts this trend brings.

1. Waste Drops, Speed Rises

Older multi-material prints took a long time and created a lot of purge waste.

In 2025, new systems:

- switch faster

- heat up faster

- waste far less filament

This means prints finish sooner and cost less to make. Even beginners can get cleaner results without large purge blocks.

2. Color Printing Becomes the New Normal

For many years, multi-color printed models were almost a “special project.”

Now, with fast switching and smarter toolheads, colorful prints are becoming everyday tools.

This helps:

- hobby makers

- small shops

- designers

- students

- prosumers who want better-looking models

More users can now create toys, art, signs, and detailed prototypes without complicated steps.

3. More Creative Materials

New systems support many materials, including:

- PLA

- TPU

- ABS

- PETG

- PVA (dissolvable supports)

- flexible and rigid mixes

This gives users the power to print soft and hard parts together, make stronger joints, or create parts with special textures.

4. A Market Led by a Few Big Brands

Brands like:

- Bambu Lab

- Prusa

- Creality

- Snapmaker

- Anycubic

- Elegoo

- Flashforge

now control over 95% of the global consumer FDM market.

Because these major brands all released multi-material systems at the same time, the whole industry is moving in one clear direction.

When big companies push a trend together, progress becomes faster and benefits reach users more quickly.

Why This Matters for You

For everyday users, this shift means:

- better print quality

- more colors and materials

- shorter waiting times

- lower waste

- more choices at different price levels

Multi-material printing is no longer a feature only for experts.

In 2025, it becomes a feature for everyone.

Final Thoughts

2025 is a special year for consumer 3D printing.

Big brands across the world are moving in the same direction. Because of this, the technology is growing faster than ever before. What once felt advanced or difficult is now becoming a normal part of desktop printing.

For beginners, this means multi-color prints with less work.

For prosumers, it means more control, better quality, and stronger materials.

For the whole market, it marks a real turning point.

Multi-material printing is no longer the future.

In 2025, it becomes the new standard.

FAQ: Multi-Material FDM Printing in 2025

1. What is multi-material FDM printing?

Multi-material FDM printing lets a 3D printer use more than one color or material in the same model.

The printer switches between different filaments during the print.

This helps create colorful models, stronger parts, or prints with soft and hard sections mixed together.

2. Why was multi-material printing hard before 2025?

Older systems were slow and messy. They needed:

- long heating times

- big purge towers

- a lot of wasted filament

- tricky setup steps

This made multi-material prints difficult for beginners and costly for everyone.

3. What changed in 2025?

New printers use:

- faster heating (like induction)

- smarter toolheads

- clean switching systems

- less or zero purge waste

These upgrades make multi-material printing much easier and faster than before.

4. Which brands lead the multi-material trend?

Major brands now developing multi-material systems include:

- Prusa

- Bambu Lab

- Creality

- Snapmaker

- Anycubic

- ELEGOO

- Flashforge

Together, these companies cover over 95% of the global consumer FDM market.

5. Why is purge waste a problem?

Purge waste is the extra filament pushed out when switching colors.

It:

- costs money

- takes time

- makes the print slower

- creates large purge blocks

New systems reduce or remove purge waste, making printing cleaner and cheaper.

6. Can beginners use multi-material printers now?

Yes.

The new systems in 2025 are much easier to use. Many printers handle switching automatically. Beginners can get clean multi-color prints without special tuning.

7. What materials can multi-material printers use?

Most systems support:

- PLA

- TPU

- ABS

- PETG

- PVA (for dissolvable supports)

Some printers can even mix soft and hard materials in the same model.

8. When will the new systems be available?

Some machines are already in testing or early release in 2025.

Others, like Prusa’s INDX upgrade, are expected in 2026.

More updates will likely arrive over the next 12–18 months.

9. Do multi-material printers cost more?

They can cost more than single-color printers, but the gap is shrinking.

As more brands join the market, prices will continue to drop and become easier for home users to afford.

10. Is multi-material printing the future of FDM?

Yes.

With cleaner switching, lower waste, and faster speed, multi-material printing is quickly becoming a new standard for consumer 3D printers.

Leave a Reply