Table of Contents

Introduction

You start a big print in the afternoon. It’s a long one.

Maybe 20 hours. Maybe 29 hours.

You walk away, do other things, go to sleep. And the next morning, you check the printer.

It stopped. The filament ran out. The print didn’t finish.

If you’ve ever felt that sinking feeling, you’re not alone.

Running out of filament near the end of a long print is one of the most frustrating moments in 3D printing. It feels especially painful when the model was almost done and everything looked perfect… until it wasn’t.

The problem is simple: you can’t always tell how much filament is really left, and long prints don’t wait for you to be nearby when the spool empties.

Why this matters more than you think

When filament runs out mid-print, a few bad things can happen:

- The print pauses and never resumes correctly

- A visible line or gap appears in the model

- Layer adhesion becomes weaker

- Or worse, the print fails completely and must be restarted

That’s why many people panic and try to “fix” the problem manually—cutting filament early, pushing a new strand in by hand, or rushing to swap spools.

Ironically, those quick fixes are often what cause the real damage.

The good news: Bambu Lab printers are built for this

Bambu Lab printers are designed to handle filament runout on purpose.

When filament truly runs out, the printer can:

- Detect the loss of filament

- Pause the print automatically

- Save the exact print position

- Wait for new filament

- Continue printing after you reload

If you use an AMS (Automatic Material System), the printer can even switch to another spool automatically, as long as it’s set up the right way.

In other words: Running out of filament is not a disaster. Not knowing what to do next is.

What this guide will help you do

In this article, I’ll walk you through:

- What actually happens inside a Bambu Lab printer when filament runs out

- How AMS auto-refill really works (and when it doesn’t)

- The safest way to handle filament runout without hurting print quality

- Common mistakes that cause gaps, jams, or failed resumes

- Simple habits that make long prints far less stressful

By the end, you’ll know exactly what to do the next time a spool runs empty—without guessing, rushing, or ruining a nearly finished print.

No products found.

What Actually Happens When Filament Runs Out on a Bambu Lab Printer

When filament runs out during a print, it can feel like something “went wrong.”

In reality, the printer is doing exactly what it was designed to do.

Let’s walk through what actually happens, step by step, in plain language.

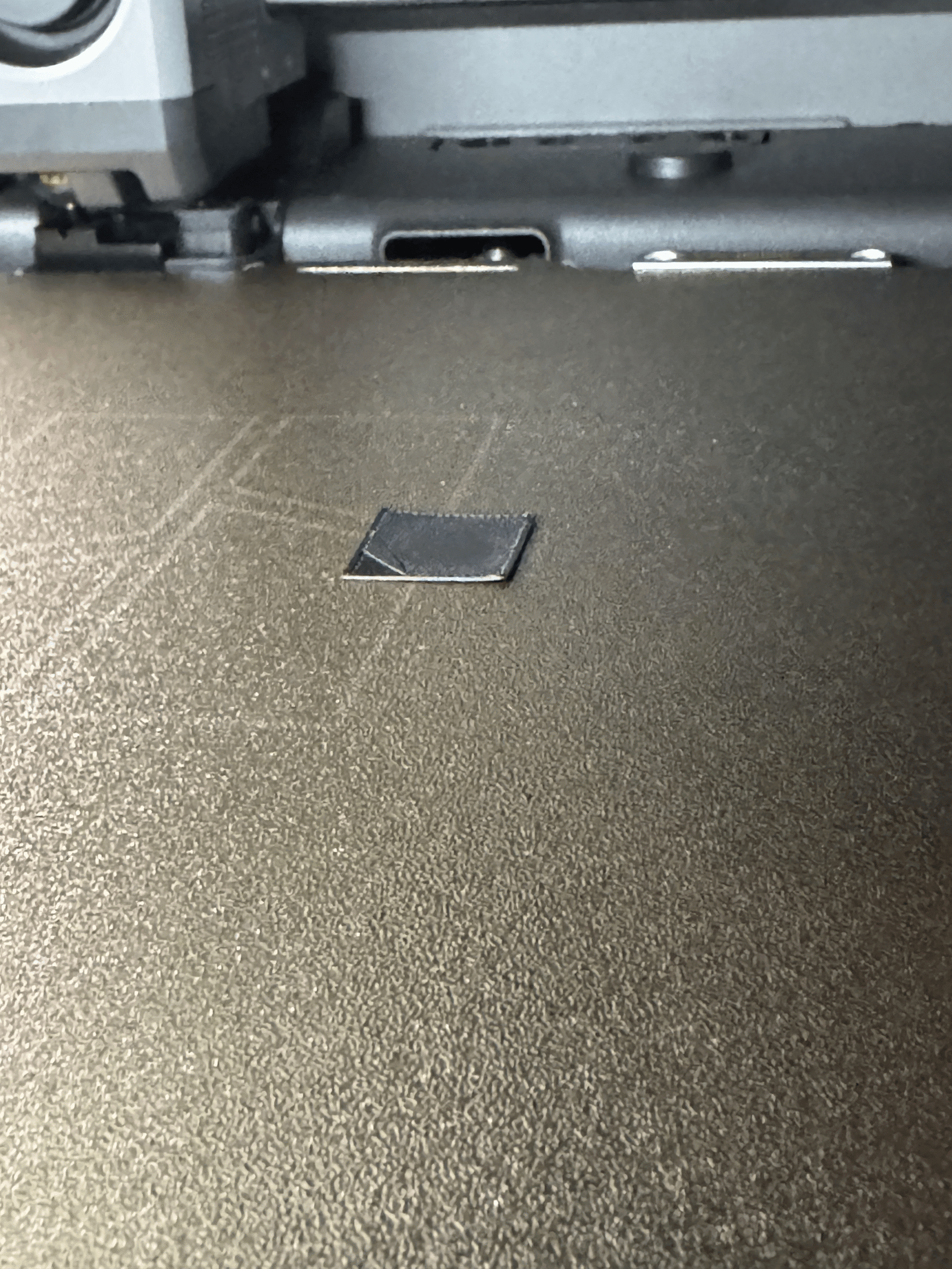

First: the printer notices the filament is gone

Inside every Bambu Lab printer is a filament runout sensor. Its only job is simple: “Is filament still moving through the system?”

When the filament is fully used and no longer reaches the sensor, the printer knows the spool is empty.

At that moment, the printer does not keep printing and it does not guess. Instead, it stops.

Then: the printer pauses the print on purpose

Once filament is gone, the printer will:

- Pause the print automatically

- Stop moving the toolhead

- Keep track of the exact layer and position

- Show a message telling you to load new filament

This pause is intentional and safe. Nothing is lost at this point.

The printer remembers:

- Where it was printing

- Which layer it stopped on

- What temperatures it needs to return to

This is why you can come back later—even hours later—and still continue the print.

After that: the printer waits for you (or the AMS)

What happens next depends on how your printer is set up.

If you do not use AMS

- The printer waits for you to load a new spool

- Once filament is loaded, you press Resume

- The printer reheats and continues printing

If you use AMS

- The printer checks if another spool is available

- If Auto Refill / Filament Backup is enabled

- And the next spool is set as the same material

→ The printer can switch spools automatically

If those conditions are not met, the printer will pause and wait—just like a non-AMS setup.

Important thing to understand: the printer does NOT predict runout

This surprises many users.

The printer does not:

- Know how much filament is left on the spool

- Switch early “just in case”

- Guess when filament will run out

It only reacts after filament is actually gone.

That’s why:

- The pause happens suddenly

- AMS switching only happens after runout

- Planning ahead matters for long prints

This is normal behavior, not a bug.

Why this system is safer than manual intervention

Some people try to be “faster than the printer” by:

- Cutting filament early

- Pushing a new filament strand behind the old one

- Swapping spools before the printer pauses

This often causes problems because:

- The printer thinks filament is still present

- Sensors get confused

- Extrusion becomes uneven

- Small gaps appear in the print

Letting the printer reach a clean, detected runout gives it a clear state to recover from.

That’s why waiting for the pause is almost always safer.

Quick summary of the runout process

When filament runs out, the printer:

- Detects no filament movement

- Pauses the print automatically

- Saves the exact print position

- Waits for new filament or AMS action

- Reheats and resumes when ready

This system exists specifically to protect long prints.

Once you understand this flow, filament runout becomes much less scary—and much easier to handle correctly.

How AMS Auto Refill Really Works

If you use a Bambu Lab printer with AMS, you might think: “If one spool runs out, the printer will just grab another one.”

That can be true — but only if AMS is set up correctly.

Most AMS problems don’t come from hardware. They come from wrong expectations.

Let’s clear this up.

What AMS is actually designed to do

AMS stands for Automatic Material System. At its core, AMS does three things:

- Stores multiple filament spools

- Feeds filament to the printer automatically

- Switches spools after one is fully used up

AMS is not trying to predict the future. It reacts only when something finishes.

Think of it like this:

AMS doesn’t ask “Is this spool almost empty?”

AMS only asks “Is this spool empty now?”

When AMS WILL auto-switch spools

AMS will automatically switch to another spool only if all of these are true:

- Auto Refill (Filament Backup) is enabled

- Another spool is already loaded in AMS

- That spool is set as the same material type

- The settings were confirmed before the print started

If even one of these is missing, AMS will stop and wait instead of switching.

The most common misunderstanding

Many people assume: “I put another spool in AMS, so it will switch automatically.”

But AMS does not work that way by default. You must tell the printer that the second spool is allowed to replace the first one.

If you don’t:

- The printer pauses

- AMS lights turn red

- The print waits for manual input

This is expected behavior, not a failure.

Material type matters more than color or brand

For AMS auto refill, material type is critical.

Safe auto-switch examples:

- PLA → PLA

- PETG → PETG

Unsafe auto-switch examples:

- PLA → PETG

- PLA → ABS

- PETG → TPU

Different materials behave differently when melted.

Switching types mid-print can cause:

- Weak layer bonding

- Warping

- Failed prints

That’s why AMS blocks these switches unless you override it manually.

About color and brand

Color and brand do not matter physically — but they matter logically.

AMS only auto-switches when the system believes the spools are the same.

That means:

- Same material type

- Same settings label

This is why some users manually label different colors as the same color in AMS settings — to allow auto refill. The printer doesn’t “see” color. It follows the settings you give it.

AMS does NOT change settings mid-print

Another important limitation: AMS settings are locked once the print starts.

That means:

- You cannot change which spool is backup mid-print

- You cannot reassign materials once printing begins

- AMS will only use what was prepared beforehand

This is why planning matters for long prints.

What happens when AMS auto refill works correctly

When everything is set up right, the process looks like this:

- Current spool fully runs out

- AMS detects the empty spool

- Printer pauses briefly

- AMS loads the backup spool

- Filament is purged and re-fed

- Printing continues

Most of the time, the transition is barely visible in the final print.

Simple takeaway for AMS users

If you remember only one thing, remember this: AMS auto refill is not automatic unless you prepare it.

Load backup spools.

Match material types.

Enable auto refill.

Confirm before printing.

Do that, and AMS becomes one of the most powerful tools for long, worry-free prints

No products found.

The Safest Ways to Handle Filament Runout (Step by Step)

When filament runs out, there are many ways to react — but only a few ways that are consistently safe.

This section shows the best workflows, depending on how your printer is set up, and explains why they work.

Option A: Let the Printer Detect Runout and Pause (Most Reliable

This is the safest and most recommended method, especially if you are not standing next to the printer.

What you do:

- Nothing — just let the printer run

What the printer does:

- Filament fully runs out

- The printer detects runout

- The print pauses automatically

- The printer waits for new filament

Then you:

- Load a new spool

- Confirm filament is loaded

- Press Resume

The printer reheats, pushes filament to the nozzle, and continues printing exactly where it stopped.

Why this works so well:

- The printer is in a clean, known state

- Sensors are not confused

- Extrusion restarts correctly

- Print quality stays consistent

If you remember only one rule, remember this:

A clean runout pause is safer than a rushed manual swap.

Option B: Use AMS Auto Refill (Best Hands-Off Solution)

If you use AMS and plan ahead, this is the smoothest option.

Before you start the print:

- Load a second spool into AMS

- Set it as the same material type

- Enable Auto Refill / Filament Backup

- Confirm everything before pressing Print

What happens during the print:

- First spool runs out

- AMS switches to the backup spool

- Printing continues with little or no pause

Why this is ideal:

- No manual action needed

- Great for overnight or long prints

- Minimal risk of gaps or weak layers

This is what AMS was designed for.

Option C: Manual Swap During a Pause (Works, but be careful)

If you don’t use AMS, or AMS auto refill isn’t set up, manual swapping still works — as long as you follow the printer’s flow.

Correct manual process:

- Wait for the printer to pause

- Remove the empty filament

- Load new filament using the printer menu

- Let the printer finish loading

- Press Resume

Important detail:

Do not rush this. Let the printer complete each step.

Skipping steps or forcing filament in early increases the chance of under-extrusion or visible seams.

What NOT to do (Common but risky habits)

These actions seem helpful, but often cause problems:

❌ Cutting filament early “to save time”

❌ Pushing new filament behind the old one

❌ Swapping spools before the printer pauses

❌ Trying to outsmart the sensors

Why these fail:

- Sensors detect filament incorrectly

- Extrusion becomes uneven

- AMS may purge unexpectedly

- Small gaps appear in the print

Many failed prints happen not because filament ran out, but because the user interfered at the wrong moment.

A simple rule that avoids most problems

When filament is running low, ask yourself: “Is the printer paused yet?”

If the answer is no, wait. If the answer is yes, follow the prompt.

Bambu Lab printers are designed to recover cleanly — but only if you let them.

Quick comparison

| Situation | Best choice |

|---|---|

| You are away | Let it pause |

| Long print, overnight | AMS auto refill |

| No AMS | Pause → load → resume |

| In a hurry | Still wait for pause |

Common Problems (and How to Fix Them)

Even if you do everything “right,” filament runout can still cause confusion. That doesn’t mean your printer is broken. Most problems fall into a few predictable patterns. Once you know them, they’re easy to fix.

Problem 1: The printer says “filament ran out,” but there’s still filament on the spool

This happens more often than people expect. The printer does not measure how much filament is left on the spool. It only checks whether filament is moving past the sensor.

So if filament:

- Gets tangled

- Stops feeding smoothly

- Pulls tight against the spool

The printer may think it’s empty even when it’s not.

What to do:

- Check the spool for tangles or tight loops

- Pull out a short length of filament by hand

- Reload the filament through the normal loading process

- Resume the print

Most of the time, this fixes the issue immediately.

Problem 2: AMS doesn’t switch to the backup spool

This is one of the most common AMS complaints — and usually not a hardware issue.

AMS will not auto-switch if:

- Auto Refill / Filament Backup is disabled

- Backup spool is set to a different material type

- Settings were changed after the print started

What to check:

- Is Auto Refill enabled?

- Are both spools set as the same material?

- Were both spools loaded before pressing Print?

If any answer is “no,” AMS is behaving normally.

Problem 3: AMS keeps pushing and pulling filament but won’t load it

You might see AMS:

- Push filament forward

- Pull it back

- Repeat the process

This usually means the filament tip isn’t entering the path cleanly.

Common causes:

- Bent or jagged filament tip

- Filament end too thick or crushed

- Sharp bend at the PTFE tube entrance

Fix:

- Remove the filament

- Cut the tip clean and straight

- Reinsert slowly

- Let AMS grab it naturally

A clean filament tip solves this surprisingly often.

Problem 4: The printer pauses, but Resume does nothing

This feels scary — but it’s usually simple. Most of the time, the printer hasn’t fully detected the new filament yet.

Try this:

- Make sure filament is fully loaded

- Confirm the printer shows filament as present

- Complete the “Load Filament” step

- Then press Resume

If Resume still doesn’t work:

- Cancel the load step

- Reload filament again

- Restart the printer if needed

The print job itself is usually still safe.

Problem 5: A visible line or seam appears after resuming

A small seam at the resume point can happen, especially on:

- Very glossy filaments

- Transparent materials

- Large flat surfaces

This is usually cosmetic, not structural.

How to reduce it next time:

- Use AMS auto refill for smoother transitions

- Avoid manual mid-print swaps

- Keep nozzle temperature stable

Most prints remain fully usable even if a seam is visible.

Problem 6: Filament breaks inside the tube or AMS path

This happens most often with:

- Old filament

- Brittle filament

- Filament exposed to moisture

What to do:

- Remove remaining filament pieces

- Clear the PTFE path

- Reload fresh filament

- Resume the print

If filament breaks repeatedly, drying or replacing the spool is the long-term fix.

How to tell if it’s user error or a real problem

Ask yourself:

- Did I wait for the printer to pause?

- Did I follow the on-screen steps?

- Did I change settings mid-print?

If you followed the printer’s flow, recovery usually works.

If you rushed or forced a step, problems are more likely.

Quick problem → solution table

| Issue | Most likely fix |

|---|---|

| Says empty but isn’t | Check tangles, reload |

| AMS won’t switch | Enable Auto Refill, match materials |

| AMS keeps retrying | Cut filament tip clean |

| Resume doesn’t work | Reload filament fully |

| Seam after resume | Mostly cosmetic |

| Filament breaks | Use fresh or dried filament |

Advanced Tips & Smart Tricks

Once you understand how filament runout and AMS really behave, you can start using that knowledge to your advantage.

These tips won’t change how the printer works—but they dramatically reduce stress, waste, and failed prints.

Tip 1: Use AMS to finish almost-empty spools

Most people hate half-empty spools. They’re not enough for a full print, but throwing them away feels wasteful.

AMS can solve this.

How to do it:

- Load several nearly empty spools into AMS

- Set them all as the same material type

- (Optional) Set them as the same color in AMS

- Enable Auto Refill / Filament Backup

- Start the print

AMS will use each spool until it runs out, then move to the next one.

This is one of the best ways to:

- Reduce filament waste

- Clean out your filament shelf

- Finish large prints without guessing spool lengths

Tip 2: Different colors are fine—if you plan for it

Physically, PLA is PLA. The printer doesn’t care what color it is.

AMS does care about settings.

If you want AMS to auto-switch between colors:

- Set both spools as the same material

- Label them the same in AMS settings

The printer follows the labels, not your eyes.

Important: This works best when color changes happen in:

- Internal layers

- Hidden surfaces

- Functional parts

For visible surfaces, expect a color shift at the switch point.

Tip 3: Plan long prints like a checklist

Before starting a long print, especially overnight, run through this quick checklist:

- Do I have a backup spool loaded?

- Is Auto Refill enabled?

- Are material types matched?

- Are spools feeding smoothly?

This takes less than a minute and can save hours or days of reprinting.

Tip 4: Manual swaps still work—if you respect the flow

No AMS? No problem.

Manual swaps are reliable when you:

- Wait for the printer to pause

- Use the printer’s load/unload process

- Let the printer finish loading before resuming

The mistake is trying to be faster than the system.

When users report gaps, jams, or weak layers, it’s almost always because they:

- Forced filament early

- Skipped a step

- Didn’t wait for confirmation

Let the printer lead. You follow.

Tip 5: Clean filament tips prevent most AMS struggles

A surprising number of AMS issues come from one thing:

Bad filament tips.

Before loading filament:

- Cut the end clean and straight

- Remove bends or crushed sections

- Avoid jagged or mushroomed tips

AMS relies on smooth feeding. A clean tip can be the difference between:

- A perfect auto-switch

- Endless push-pull retries

Tip 6: Dry filament breaks less during runout

Filament that snaps easily is far more likely to:

- Break inside the tube

- Jam during auto-switch

- Fail during reload

If you see filament breaking near runout:

- Dry the spool

- Replace old filament

- Avoid brittle material for long prints

Dry filament makes runout recovery boring—and that’s a good thing.

The “advanced user” mindset

Advanced users don’t fight the printer.

They:

- Plan ahead

- Use AMS intentionally

- Let sensors do their job

- Avoid rushing

That’s why their long prints succeed more often—not because they’re lucky, but because they’re prepared.

FAQ

Will running out of filament ruin my print?

No.

Bambu Lab printers are designed to pause automatically when filament runs out. The printer saves its position and waits for new filament. As long as you reload correctly and resume, the print can finish normally.

Can the printer continue printing after I change filament?

Yes.

Once new filament is loaded and detected, pressing Resume will continue the print from where it stopped. This works with or without AMS.

Does AMS automatically switch to another spool?

Yes—but only if it’s set up beforehand.

AMS will auto-switch only when:

- Auto Refill / Filament Backup is enabled

- Another spool is already loaded

- The backup spool is set as the same material type

If those conditions aren’t met, the printer will pause and wait.

Do the filament colors need to match for auto refill?

Not physically—but logically, yes.

AMS follows the settings, not the actual color.

If you label two spools as the same material and color in AMS, the printer will treat them as interchangeable—even if the real colors are different.

Can I switch filament mid-print without AMS?

Yes.

The printer will pause when filament runs out and ask you to load a new spool. After loading, press Resume and the print continues.

Why does the printer say filament ran out when there’s still filament left?

This usually happens because:

- The filament is tangled

- The spool is feeding poorly

- Filament stopped moving past the sensor

Reloading the filament cleanly often fixes the issue.

Why won’t AMS switch to my backup spool?

The most common reasons are:

- Auto Refill is turned off

- The backup spool is set as a different material

- Settings were changed after the print started

AMS does exactly what it’s told—nothing more.

Why does AMS keep pushing and pulling filament?

This usually means the filament tip isn’t feeding smoothly.

Fix it by:

- Removing the filament

- Cutting a clean, straight tip

- Reloading slowly

A clean tip solves many AMS problems.

I pressed Resume, but nothing happens. Why?

Most of the time, the printer hasn’t fully detected the new filament yet.

Make sure:

- Filament is fully loaded

- The load process is completed

- The printer confirms filament is present

Then press Resume again.

Will there be a visible seam after resuming?

Sometimes, yes—but usually it’s cosmetic.

Seams are more noticeable on:

- Glossy filament

- Transparent materials

- Large flat surfaces

AMS auto refill reduces visible transitions compared to manual swaps.

Does AMS waste filament in the tube when switching?

Yes.

AMS purges the filament left in the tube when a spool runs out. This ensures clean feeding, but a small amount of filament is sacrificed for reliability.

Can I mix different filament brands with AMS?

Yes, as long as:

- The material type is the same

- You set the spools with matching settings

Brand does not matter to the printer—settings do.

One simple rule to remember

Let the printer pause first.

Then follow the prompt.

Most filament runout issues become easy once you stop rushing the process.

Appendix — Quick Checklist & Reference Guide

This section is not meant to be read once.

It’s meant to be used.

If you print large models, long jobs, or overnight prints, this checklist can save you hours.

Pre-Print Filament Runout Checklist (1 Minute)

Before starting a long print, quickly check the following:

🔹 Filament & Spools

- Filament feeds smoothly (no tangles)

- Filament tip is cut clean and straight

- Filament is dry (especially for PETG, TPU, ABS)

🔹 If You Use AMS

- Backup spool is already loaded

- Backup spool is set as the same material type

- Auto Refill / Filament Backup is enabled

- AMS settings confirmed before pressing Print

🔹 If You Don’t Use AMS

- You’re okay with a pause mid-print

- You know where the Resume button is

- Replacement filament is ready nearby

This entire check takes less than a minute—and prevents most runout failures.

Quick Decision Guide

Filament is running low. What should I do?

- Print not paused yet? → Wait

- Printer paused automatically? → Load filament, then Resume

- Using AMS with backup ready? → Do nothing

- In a rush? → Still wait for the pause

If you’re unsure, the safest move is always to let the printer decide first.

AMS Auto Refill — At a Glance

AMS will auto-switch only if:

- Auto Refill is enabled

- Backup spool is already loaded

- Material type matches

- Settings were set before printing

AMS will NOT:

- Predict filament runout

- Switch early

- Change settings mid-print

Remember:

AMS follows rules.

It does not guess.

Common Mistakes to Avoid (Bookmark This)

- ❌ Cutting filament early

- ❌ Pushing new filament before pause

- ❌ Changing AMS settings mid-print

- ❌ Ignoring bent or messy filament tips

- ❌ Assuming AMS “just knows” what you want

Almost every horror story starts with one of these.

Troubleshooting Shortcut

If something goes wrong, ask in this order:

- Is filament detected?

- Is filament loaded cleanly?

- Did the printer finish the load step?

- Are AMS settings correct?

- Did I rush anything?

Answering these five questions solves most issues.

Final Note

Long prints don’t fail because filament runs out.

They fail because people panic when it happens.

Once you trust the pause-and-resume system—and prepare AMS properly—filament runout becomes a non-event.

Save this page.

Use the checklist.

Let the printer do its job

Leave a Reply