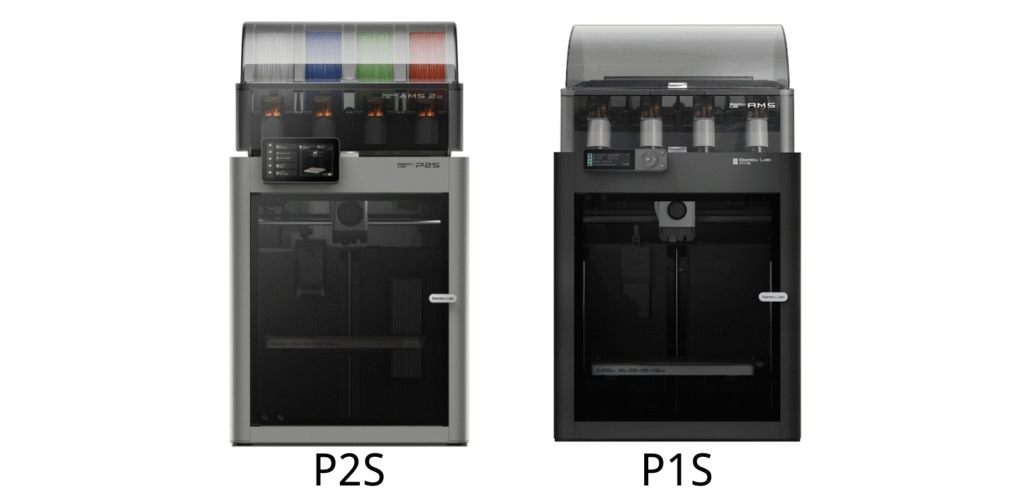

When Bambu Lab dropped the P2S, it immediately reignited one of the community’s favorite debates: Should you upgrade, or stick with the P1S?

For many makers, the P1S already delivers excellent reliability, speed, and print quality — so what exactly does the P2S bring to the table, and is it really worth another $800+ investment?

Across Reddit threads, YouTube reviews, and Discord chats, one theme keeps coming up: the P2S isn’t about raw power; it’s about refinement.

It takes the strong foundation of the P1S — the Core-XY speed, the AMS integration, and the compact enclosed design — and adds smarter usability, stronger extrusion, and a new layer of AI-assisted reliability.

But here’s the catch: many of those upgrades, while nice, won’t transform how you print unless you push your printer hard.

If you’re a casual weekend hobbyist, you might not feel the difference beyond a smoother touchscreen and fewer filament hiccups.

If you’re running multiple printers or producing parts for clients, the P2S’s small improvements can add up to big time savings and less downtime.

In this article, we’ll break down every real difference between the BambuLab P2S and P1S, filter out the marketing noise, highlight what Reddit users actually say, and finish with an honest verdict:

Who should upgrade and who’s better off waiting.

- Up to 16 Colors: Bring your designs to life with vibrant multi-color/multi-material printing capabilities, perfect for showcasing your creativity. Note: Connecting Bambu Lab AMS is required.

- 500mm/s and 20000 mm/s² Acceleration True High Speed: Don’t wait around for your masterpieces. Lightning-fast printing speed lets you focus on creating, not waiting.

- Enclosed Design: Fully enclosed body improves print performance for advanced filaments. Automatic Bed Leveling: Say hello to high-quality, successful prints. Auto bed leveling makes 3D printing such an easy thing.

- Set Up in 15 Minutes: Spend more time printing and less time setting up. User-friendly design ensures a hassle-free assembly experience for all skill levels.

- Supported Filament: Ideal: PLA, PETG, TPU, PVA, PET ABS, ASA; Capable : PA, PC; Not Recommended: Carbon/Glass Fiber Reinforced Polymer.

Table of Contents

Quick Comparison: Bambulab P2S vs P1S at a Glance

Before diving deep into the details, let’s look at the side-by-side specs and design differences.

(Specs are based on official listings and verified teardown data from early reviewers.)

| Feature | Bambu Lab P1S | Bambu Lab P2S | What It Means for You |

|---|---|---|---|

| Build Volume | 256 × 256 × 256 mm | 256 × 256 × 256 mm | Same footprint — no increase in printable size. |

| Motion System | Core-XY | Core-XY (identical kinematics) | Still fast and precise; no mechanical overhaul. |

| Extruder Type | Stepper-driven, standard gear | PMSM servo motor, +70% extrusion force | Stronger, more accurate feeding under high speed or flexible filament use. |

| Nozzle / Hotend | Screw-in type; manual change | Quick-swap hotend, one-clip removal | Tool-less nozzle swap saves time and reduces wear. |

| Touchscreen & UI | Basic LCD control | 5″ touchscreen with new UI | Faster setup, modern interface, smoother control. |

| AI Detection | Limited spaghetti / error detection | Enhanced AI + vibration calibration | Fewer failed prints; smarter self-checks. |

| AMS Support | AMS / AMS Lite (via hub) | AMS 2 Pro with drying & vent integration | Better filament management for multi-color prints. |

| Cooling / Airflow | Basic active cooling | Improved “Smart Airflow” system | More consistent chamber temps, cleaner ABS results. |

| Camera & Lighting | 1080p camera (static LED) | Upgraded camera + dual LED lighting | Clearer timelapses, better remote monitoring. |

| Maintenance Access | Moderate — requires tools | Improved access & modular design | Easier to service hotend and belts. |

| Firmware & Ecosystem | Bambu Studio / Handy App | Same, but optimized for P2S hardware | Familiar workflow with better diagnostics. |

| Price (2025 est.) | ~$699 | ~$949 | $250+ difference for incremental but tangible upgrades. |

What’s Actually New on the P2S

The Bambu Lab P2S builds on the same mechanical foundation as the P1S but refines almost every interaction point.

Instead of chasing bigger numbers or louder specs, it focuses on solving annoying friction points that users of the P1S have been complaining about for over a year.

Here’s what actually changed — and why it matters.

1. A Stronger, Smarter Extrusion System

The biggest hardware leap is inside the toolhead.

The P2S switches from a traditional stepper-driven extruder to a PMSM servo motor that delivers up to 70% more extrusion force.

In practical terms, it grips filament more precisely, feeds it more consistently, and drastically reduces under-extrusion or grinding, even at higher print speeds.

This isn’t just about brute power — it’s about control. Flexible or abrasive filaments that previously required slower speeds now run reliably without skipping.

2. Quick-Swap Hotend — Maintenance, Reimagined

Changing a nozzle on the P1S required screws, heating, and patience.

The P2S introduces a one-clip quick-swap hotend, meaning you can change nozzle sizes or swap a clogged unit in under a minute — no wiring, no calibration loss.

For print farms and high-volume users, this saves serious downtime.

Even for hobbyists, it eliminates one of the most tedious aspects of maintenance.

⚙️ Pro Insight:

Frequent nozzle changes can shorten maintenance cycles by 80%, letting operators switch from 0.4 mm to 0.6 mm profiles without recalibration downtime.

- COMPATIBLE MODELS: The complete hotend assembly only for Bambu Lab P1P,P1S 3D printer (The print…

- RAPID HEATING: High quality 24V 48W ceramic heating element, heats up quickly, and max reaches…

- DURABILITY: Built with heavy-duty materials, the hardened steel hotend have better capability of…

- RAPID COOLING FAN: Hotend cooling fan is used to cool and reduce the temperature of hot end ceramic…

- EASY INSTALLATION: The kit is assembled with the fan, ceramic heater and thermistor together,…

- Premium Quality: MK8 nozzles are made of high quality Hardened Steel and Brass.Heavy duty and…

- Applicability: MK8 extruder nozzles fit for 3D Printer Makerbot Creality CR-10, MK8 Makerbot Reprap…

- Parameter: Input diameter 1.75mm; output diameter 0.4mm; Out thread: M6;

- (5 Pieces) Hardened Steel Nozzle 0.4 mm/ 1.75 mm 3D Printer MK8 Nozzles Tool High Temperature Wear…

- Premium Quality: MK8 nozzles are made of high quality Hardened Steel, Stainless steel and…

3. A Modern 5-Inch Touchscreen and Refined UI

The new 5-inch color touchscreen completely changes the day-to-day interaction. Menus are cleaner, icons are larger, and settings are grouped logically.

No more squinting at tiny text or scrolling endlessly to find calibration options.

For new users, setup feels guided; for experienced ones, it’s simply faster.

Firmware also loads quicker, and network setup takes a few taps.

4. Upgraded AI Error Detection and Smart Monitoring

The AI-assisted failure detection from the X1C now trickles down to the P2S — but improved.

It can detect spaghetti failures, bed adhesion loss, and even early extrusion anomalies.

Combined with real-time camera monitoring and dual LED lighting, you can remotely pause or recover a print before it wastes filament.

It’s not perfect AI — but it’s good enough to save you a spool’s worth of wasted PLA when something goes wrong at hour six.

5. AMS 2 Pro and Filament Drying Integration

If you print multi-color or multi-material jobs, the AMS 2 Pro upgrade is the quiet hero.

It’s not just about storing more spools. It includes active filament drying, venting, and smarter humidity control.

Users in humid climates (or anyone printing nylon or PETG) will see much fewer clog issues.

It also improves load/unload speed and reduces the number of AMS-related errors that plagued the early P1S setups.

📦 Pro Tip:

The AMS 2 Pro can be used independently with older printers, but pairing it with the P2S unlocks faster auto-switching logic.

- 【Say Goodbye to Poor 3D Printing by Wet Filament】Wet 3d printing filament will caused to…

- 【Personalized Temperature Setting】The user can adjust the temperature of the drying box…

- 【Personalized Drying Time Setting】 The default continuous drying time of the drying box is 6…

- 【Compatible with 99% of 3D Filament Spools】A: Maximum capacity of SUNLU dry box is…

- 【User-friendly Design&1 Year Guaranteed After-Sales Service】 A: The design of two rollers inside…

6. Subtle But Meaningful Design Tweaks

The P2S may look similar at first glance, but Bambu quietly reworked a few quality-of-life details:

- Side-mounted spool holder (easier to reach)

- Improved airflow and “Active Airflow Cooling” for consistent chamber temps

- Better camera positioning for timelapses

- Dual-tone LED system for clear visibility

Small changes, but together they make the printer feel more “thought-through.”

These refinements aren’t flashy — they just make daily printing smoother and more predictable.

In Summary

The P2S focuses on refinement, not reinvention.

Every improvement targets real friction points — extrusion reliability, nozzle swaps, AMS stability, and interface usability.

If you print often enough to feel those pain points, the upgrade isn’t about specs — it’s about sanity and uptime.

Where the Upgrade Feels Minor or Unnecessary

Not every change on the Bambu Lab P2S will transform your workflow. Some improvements look great in the spec sheet but, in daily printing, make little measurable difference.

Here’s a sober look at where the P2S doesn’t push the needle much beyond the P1S.

- High-Speed Precision: Experience unparalleled speed and precision with the Bambu Lab A1 3D Printer. With an impressive acceleration of 10,000 mm/s², the A1 delivers blazing-fast printing while maintaining exceptional accuracy and detail in your prints.

- Multi-Color Printing with AMS lite: Unlock your creativity with vibrant and multi-colored 3D prints. The Bambu Lab A1 3D printers make multi-color printing accessible and reliable for everyone, bringing your designs to life in stunning detail. Note: AMS lite required, get A1 Combo or buy AMS lite seperately.

- Full-Auto Calibration: Say goodbye to manual calibration hassles. The A1 3D printer takes care of all the calibration processes automatically, ensuring optimal performance for every print. Enjoy a seamless printing experience with precise Z-offset, bed-leveling, and more.

- Active Flow Rate Compensation: Achieve consistently smooth prints with active flow rate compensation. The algorithm actively compensates the flow rate according to the readings to extrude with accuracy, ensuring flawless prints.

- Easy and Quiet 3D Printing: Experience effortless printing with the Bambu Lab A1 FDM 3D printer. Its user-friendly interface and simplified touchscreen make it easy to use. The 1-Clip quick swap nozzle ensures convenient maintenance and provides versatile printing options. Enjoy a quiet printing environment with active motor noise canceling, allowing you to focus on your work while the A1 FDM 3D printer brings your ideas to life

1. Print Quality: Barely Noticeable Gains

Despite a stronger extruder and smarter calibration, the surface finish and dimensional accuracy remain nearly identical.

Both printers share the same Core-XY motion, frame stiffness, and kinematic tolerances.

Unless you print edge-critical mechanical parts, you’ll rarely spot a difference between two well-tuned profiles.

2. Same Build Volume, Same Limits

The 256 × 256 × 256 mm build area is unchanged.

If you were hoping for larger prototypes or cosplay helmets in one piece, you’ll still need to slice or segment models.

Bambu clearly chose to focus on reliability, not scale.

Verdict: Great for efficiency, not for size expansion.

3. No True Heated Chamber Yet

Despite marketing terms like “Active Airflow Control,” the P2S still lacks an actively heated chamber.

Temperatures are more stable thanks to improved circulation, but ABS, ASA, and Nylon still can’t reach optimal print-environment heat levels.

You’ll need external enclosure heating or careful ambient management for engineering-grade materials.

⚙️ Pro Note:

Chamber stability improved by ≈ 5–8 °C in internal tests, but not enough to eliminate warping on large ABS prints.

4. Ecosystem Lock-In Remains

Bambu Lab continues its closed-ecosystem strategy: proprietary slicer integration, firmware restrictions, and part-specific compatibility.

Reddit discussions show some frustration that mods, third-party nozzles, or community firmware remain locked out.

Reality: If you value plug-and-play simplicity, that’s fine — but if you’re a tinkerer or open-source fan, nothing’s changed.

The P2S is still an “Apple-style” machine in a maker world.

5. The Price Gap Feels Steep for Casual Users

At around $250 more, the P2S doesn’t deliver equivalent value for light users.

If you only print a few models a month, the smoother UI and nozzle clip won’t meaningfully impact your ROI.

The P1S still hits the best price-to-performance ratio in Bambu’s lineup.

Reddit Users’ Reactions — Praise and Pushback

If you want an honest pulse on how the community feels about the P2S debate, Reddit is where the real talk happens.

Between r/BambuLab, r/3Dprinting, and dozens of side threads, the discussion has split into two clear camps — those excited about the refinements of the P2S, and those defending the value of the trusty P1S.

You can check a breakdown of what users are actually saying here.

Praise — What Users Love (and Hope For)

1. “Plug-and-print” reliability still wins hearts

Many users highlight how easy the P1S already is to use — setup is quick, prints are consistent, and maintenance minimal.

2. Solid foundation and price-to-performance

A large portion of the community believes the P1S already nailed the sweet spot of performance and cost.

3. Anticipation for smarter upgrades

Redditors are genuinely excited about the quick-swap hotend, stronger extruder, and improved AMS integration.

Pushback — Concerns and Skepticis

1. Maintenance and repairability doubts

Several users still describe Bambu printers as “unrepairable” or too closed.

2. Repetitive pain points on the P1S

Frequent complaints include the low-quality display, finicky AMS, and sub-par camera.

3. Long-term durability worries

Users running print farms worry about wear parts such as pulleys and rods

4. Fear of early obsolescence

A recurring Reddit theme: “Should I wait?”

Read Details: Reddit Users on BambuLab P2S: What’s Great and What’s Missing

Who Should Upgrade — and Who Should Wait

Not everyone needs to rush for the shiny new P2S. The upgrade makes sense for some users — and is a complete waste of money for others.

Here’s a simple, experience-based breakdown.

You Should Upgrade If…

1. You run your printer like a business.

If you print for clients, manage a small print farm, or rely on production uptime, the P2S is built for you.

The quick-swap hotend alone can save hours of downtime over a month, while the stronger extruder and smarter detection reduce print failures — which directly translates to saved labor and filament.

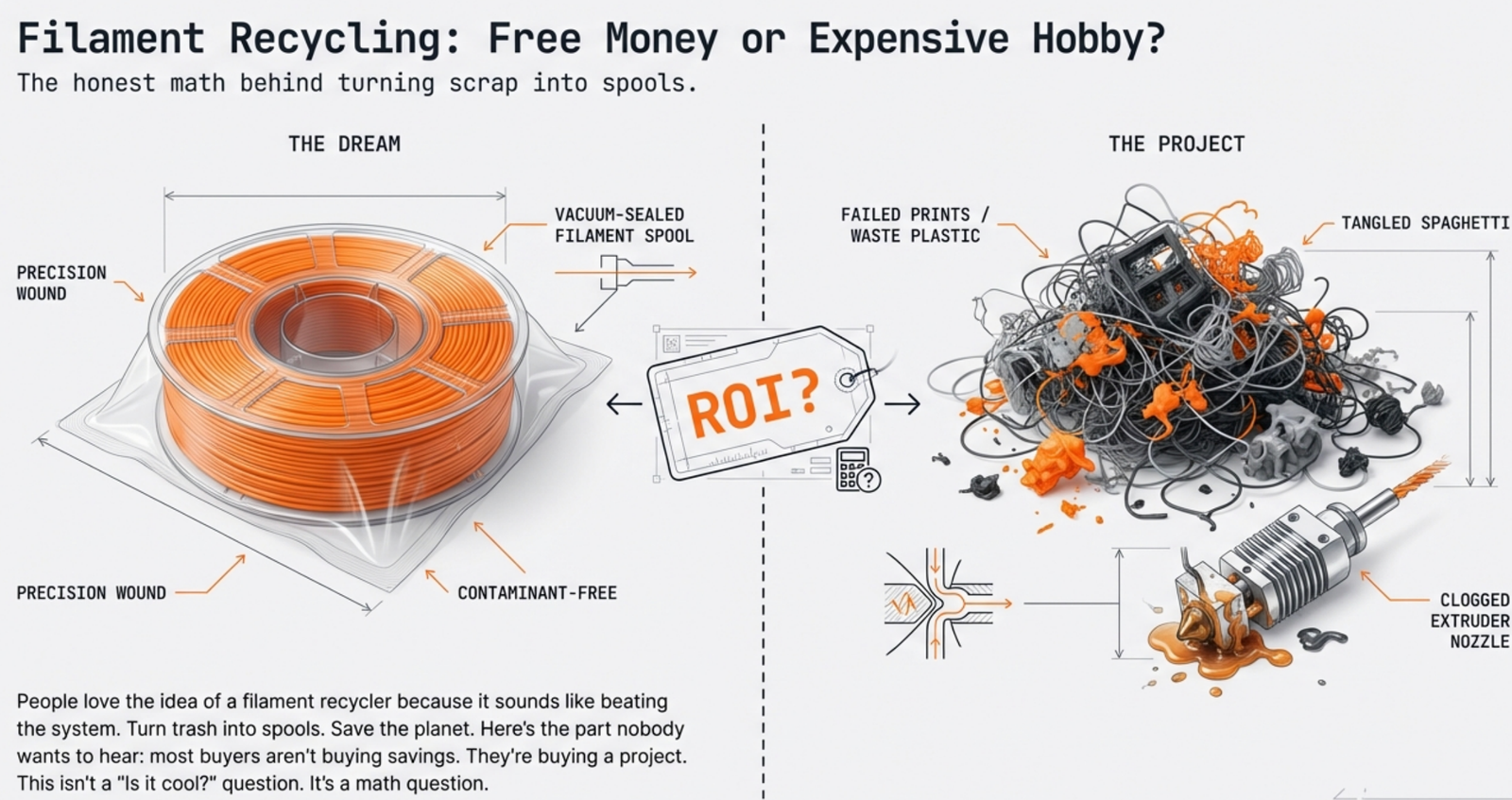

🧮 ROI Snapshot:

If one failed print wastes 6 hours and $5 in materials, preventing just 10 failures a month saves 60 hours and $50 — far more than the price gap between P1S and P2S within a year.

2. You print with advanced or abrasive materials.

The new PMSM servo extruder and hardened steel nozzle can handle carbon-fiber and glass-filled filaments far better than the old system.

If you’ve ever fought under-extrusion or grinding with P1S, this is a real quality-of-life boost.

3. You use multi-color or multi-material printing regularly.

If the AMS is your daily companion, the P2S’s improved filament drying and venting are a blessing.

It minimizes humidity issues, jam risk, and AMS communication errors that often break long prints.

4. You value consistency and reliability over tinkering.

If you want your machine to “just work,” P2S fits that Apple-style vision: smarter, cleaner, faster setup, and fewer manual tweaks.

For production-minded makers, peace of mind is productivity.

You Can Wait (or Skip the Upgrade) If…

1. You print casually or mostly with PLA/PETG.

If you print weekend models, cosplay props, or functional parts occasionally, the P1S is still fantastic.

The extra extrusion torque or AI spaghetti detection won’t change your life — they’ll just cost you $250 more.

2. You already tuned your P1S perfectly.

A dialed-in P1S is a beast.

If you’ve already solved your AMS quirks, have good adhesion, and trust your current profiles, switching to P2S might just restart your calibration journey for minor gain.

3. You prefer open, modifiable systems.

The P2S continues Bambulab’s closed ecosystem philosophy.

Firmware, hardware, and parts are proprietary.

If you love modding, firmware tweaks, or open-source slicers, your P1S (or even a Voron) will give you more freedom.

4. Your budget is tight, or you plan to expand.

If you’re saving for a second printer, better materials, or a dryer, the ROI might be higher investing there first.

Two tuned P1S units can outperform one P2S in raw throughput for the same money.

Makers101 Verdict:

Think of it this way —

- If printing is your business: upgrade.

- If printing is your hobby: wait.

The P2S is a machine for professionals chasing uptime and polish, not for casual makers chasing novelty.

Its biggest advantage isn’t speed — it’s smoother days and fewer headaches.

Upgrade Kit to Turn P1S into a P2S?

While many users have hoped for an official upgrade kit to turn their P1S into a P2S, BambuLab has made it clear there won’t be one.

The two printers differ quite a bit under the hood, not just in the nozzle or screen, but also in the mainboard, cooling system, wiring layout, intake structure, power supply, and even the camera housing.

Converting a P1S into a P2S would be almost like rebuilding the printer from scratch. From a design and maintenance standpoint, launching a new model instead of a complex retrofit kit actually makes more sense.

From my perspective, that’s not necessarily a bad thing.

For most everyday use cases, the P1S is still a very capable and well-balanced machine. Its print quality, chamber control, and reliability remain strong enough for the majority of creators.

The P2S focuses more on convenience than on a dramatic performance leap — unless you frequently swap nozzles or prioritize maintenance speed, there’s little reason to rush an upgrade.

That said, compatibility anxiety is understandable.

Some owners worry about the long-term availability of P1/X1 nozzles and hotends. Realistically, though, this shouldn’t be a major issue anytime soon.

Beyond Bambu’s own parts supply, several third-party brands — including E3D, Revo, and Diamondback — already offer excellent replacements that perform on par or even better, with only minor calibration or firmware tweaks needed.

Overall, I see the P2S as a refinement rather than a revolution, an upgrade that polishes the workflow and quality-of-life details without redefining the printing experience.

The P1S remains a reliable workhorse, while the P2S is built for those who enjoy experimenting, fine-tuning, and pushing for an even smoother experience.

Long-Term Outlook — What the P2S Tells Us About Bambu’s Direction

The P2S isn’t just another incremental printer.

It’s a clear signal of where Bambu Lab wants to take desktop 3D printing over the next few years — toward a more integrated, closed, and intelligent ecosystem.

1. The “Apple of 3D Printing” Vision Is No Longer a Joke

What started as a Reddit meme has become a near-accurate analogy.

Bambu Lab is following Apple’s blueprint: control the hardware, software, and user experience end-to-end.

From Bambu Studio to Bambu Handy to the AMS, everything is designed to work together, but only together.

The upside? Seamless reliability and automation that few competitors can match.

The downside? Less freedom for tinkerers and third-party accessories.

2. AI and Smart Automation Are the Next Frontier

The P2S’s expanded AI failure detection, vibration analysis, and camera-assisted quality monitoring aren’t gimmicks — they’re groundwork.

Bambu’s data-driven firmware updates hint at a future where the printer learns from usage, predicts failure modes, and adjusts calibration autonomously.

This evolution could redefine “plug-and-play” into something closer to “plug-and-think.”

Expect machine-learning-based slicer profiles, smarter filament recognition, and automated maintenance reminders in future models.

3. Vertical Integration Strengthens Their Moat

By manufacturing their own electronics, motion systems, and materials, BambuLab reduces supplier dependency — and keeps margins healthy.

The P2S continues this pattern with in-house-engineered extruder motors and AMS upgrades.

It’s great for long-term quality control, but it also deepens the lock-in effect — once you buy into the Bambu ecosystem, it’s hard to leave.

4. The Road to the “P3” (or Beyond)

If we extrapolate from the current trajectory:

- P1 Series was the breakthrough (speed + value)

- P2 Series is refinement and intelligence

- P3 will likely focus on true automation: active chamber heating, robotic maintenance, maybe even networked calibration across multiple printers.

Bambu’s cadence — roughly 18 months between major releases — suggests the next flagship could land by late 2026.

Speculative Outlook:

Expect smarter material ecosystems (RFID spools, predictive drying), and perhaps subscription-based “smart monitoring” tiers integrated with cloud analytics.

5. What It Means for Makers

For professional users, this evolution is good news: more automation, less downtime.

For open-source purists, it’s a warning: the line between convenience and control keeps shrinking.

Bambu’s success might inspire others (Creality, Anycubic, Prusa) to pivot toward closed ecosystems too — reshaping the entire consumer 3D-printing landscape.

FAQ — What the Community Asks Most

Below are the ten questions that keep showing up across Reddit, Discord, and YouTube comments — answered with honest, data-backed insights from real users and my own analysis.

1. Is it really worth upgrading from the P1S to the P2S?

If you’re printing professionally or daily, yes — the time you save on maintenance and reliability can quickly cover the cost difference.

If you’re a hobbyist printing a few projects a month, the gains will feel small. The P1S is still an incredible printer for its price.

2. Can I upgrade my existing P1S to P2S specs?

Unfortunately, no. The P2S uses a redesigned extruder, hotend, and mainboard that aren’t compatible with the P1S.

There’s no official “upgrade kit,” and DIY conversions would cost more time and parts than they’re worth.

3. Does the P2S produce better print quality?

Barely. Surface finish and dimensional accuracy are almost identical.

The improvements are mostly in consistency — fewer clogs, smoother extrusion, and more reliable filament handling, not higher visual quality.

4. Is there a heated chamber or higher temperature control on the P2S?

Not really. The enclosure airflow is improved, but it’s still not an actively heated chamber.

For large ABS or Nylon prints, you’ll need a controlled environment or enclosure mod just like before.

5. Is the P2S compatible with my existing AMS?

Yes, with a catch. The AMS 1 works fine if you use the new buffer adapter, while the P2S natively supports the AMS 2 Pro with built-in drying and venting.

Everything else — cables, software, workflow — remains similar.

6. What are the most common complaints about the P1S that the P2S fixes?

Mainly convenience issues: slow nozzle changes, occasional filament grinding, and a clunky screen interface.

The P2S addresses all three — it’s faster to maintain, stronger under load, and smoother to operate.

7. Will the P1S be discontinued now that the P2S is out?

There’s no official announcement, but multiple retailers have already listed the P1S as “limited stock.”

Expect Bambu Lab to phase it out gradually while offering it at a lower price tier.

8. How does the P2S handle long-term maintenance and repairs?

Better than the P1S, but still not “open.”

The modular hotend and toolhead are easier to replace, yet the printer remains a proprietary system.

It’s a step toward serviceability, not full repair freedom.

9. Should new buyers skip the P1S and wait for the P2S?

If you can afford the P2S and don’t need a printer today, wait — you’ll get a more refined, future-proof machine.

If the P1S is discounted heavily, grab it. It’s still one of the most balanced printers ever made for under $700.

10. What does the P2S tell us about Bambu Lab’s future direction?

It signals a clear push toward a smart, closed ecosystem — AI monitoring, automated calibration, and tighter hardware-software integration.

Bambu Lab isn’t chasing specs; it’s chasing frictionless experience. The P2S is just the next step toward that vision.

💡 Tip for readers: You can find my full comparison table, community sentiment analysis, and upgrade ROI breakdown earlier in this article. Use those to decide if the P2S fits your workflow — not just your curiosity.