If you’ve ever packed up after a scan and only noticed the missing surface back at your desk, you know the real cost isn’t the scan—it’s the re-scan.

That’s the gap the Creality Sermoon P1 is built to close: a self-contained workflow with onboard processing and a Full HD touchscreen, so you can verify coverage and generate a basic mesh on-site, without staying tethered to a PC.

- ➤【High-Precision Dual-Technology Scanning】-Master any scanning challenge with dual-engine precision. The Sermoon P1 combines Blue Laser and…

- ➤【Flexible Standalone & PC Connected Modes】-Work freely anywhere. Operate completely independently using the built-in 6-inch touchscreen and…

- ➤【Complete All-in-One Portable Kit】-Ready to scan right out of the box. The package includes: the scanner, high-precision glass calibration…

- ➤【Smart & Simplified Data Processing】-Transform scans into models in just a few steps. Use intuitive built-in tools to seamlessly fuse, align,…

- ➤【Professional Hardware for Unmatched Performance】-Powered by pro-grade specs to handle complex data with ease. Featuring 24GB RAM, 256GB…

TL;DR

Think of the P1 as a “quasi-industrial” scanner: not a hobby handheld, not a lab-only metrology rig—something in between.

- Standalone workflow: onboard processing + Full HD touchscreen for immediate verification + basic mesh generation (no PC required)

- Optical architecture: five-camera array + multi-light setup to balance tracking stability and data density

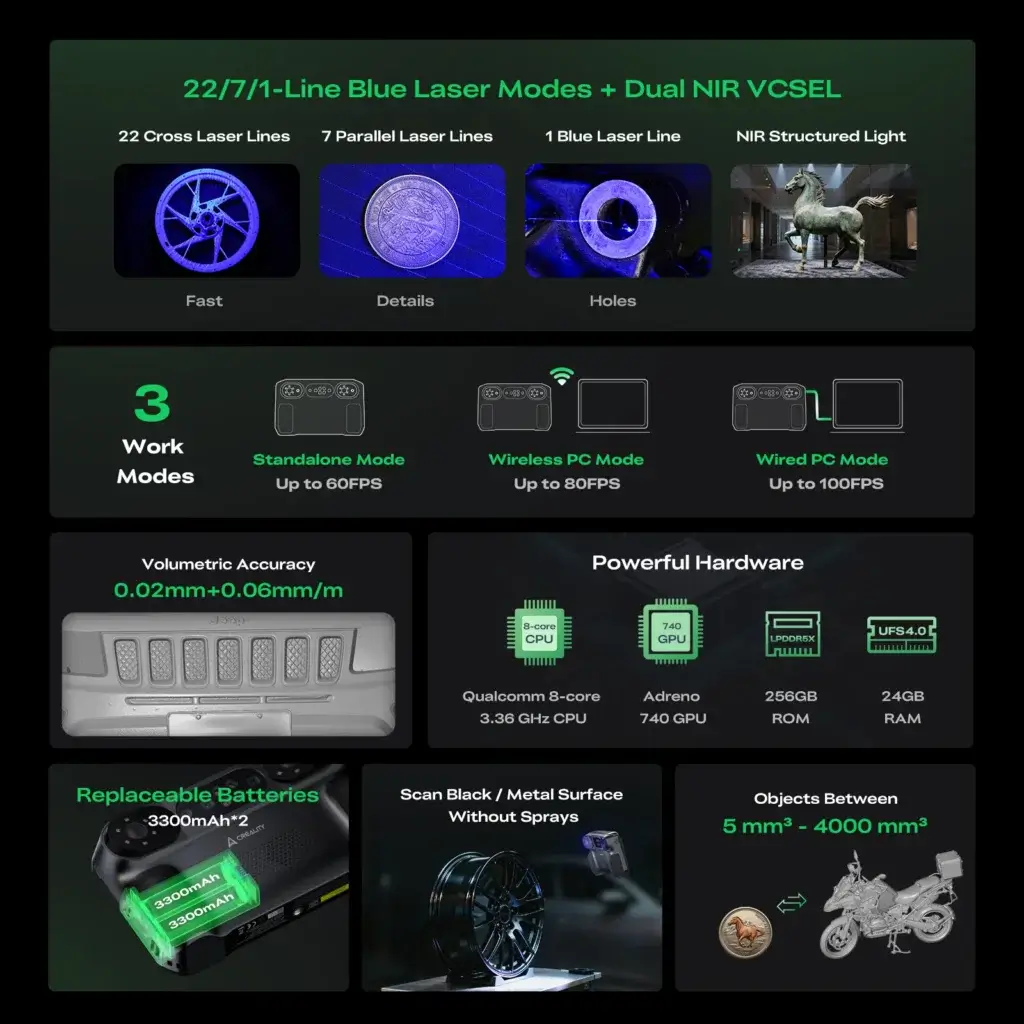

- Blue laser tri-mode: 34-line (fast coverage) / 7-line (detail) / single-line (deep holes, grooves, recesses)

- Infrared mode: structured light for faces/bodies/sculptures, No Marker scanning, plus RGB texture capture for digital twins

- Accuracy metrics: precision up to 0.02mm; volumetric accuracy 0.02mm + 0.06mm/m; point distance 0.02–2mm

- MSRP: $3299

Table of Contents

Strategic Positioning and Technical Introduction

Portable 3D metrology has always had a tradeoff:

- Industrial precision usually meant being tethered to a powerful workstation.

- Portable autonomy often meant weaker point-cloud density or less reliable volumetric integrity.

The Sermoon P1 takes a different route. It integrates a dedicated processing unit and a high-definition touchscreen, so you can verify scan data and generate a mesh immediately, without a PC connection.

It’s positioned as a “quasi-industrial” high-precision scanner designed to bridge hobby handhelds and lab-only tools. At $3,299, it aims to modernize acquisition in manufacturing, automotive, and heritage environments by reducing “re-scan” costs through on-site coverage verification.

Optical Hardware Architecture and Sensor Array

Metrology-grade capture isn’t just one sensor doing everything. The P1’s design relies on a synchronized camera and lighting system to keep tracking stable while maintaining dense data.

Sermoon P1 Optical System Components

| Component | Functionality |

|---|---|

| RGB Camera | High-fidelity color capture for accurate texture and digital twin mapping. |

| High-Precision Cameras (x2) | Dual-sensor metrology array for high-density point cloud acquisition. |

| Wide-Angle Cameras (x2) | Secondary array for expanded Field of View (FOV) and robust feature tracking. |

| Infrared Fill Lights (x4) | Specialized illumination for markerless tracking in Infrared Mode. |

| Blue & White Fill Lights (x12) | Multi-purpose lighting for color fidelity and marker recognition. |

| DOE Projector | Diffractive Optical Element for structured light projection in organic modes. |

Why the Dual Camera Pairing Matters

The advantage comes from pairing High-Precision and Wide-Angle cameras:

- High-precision cameras focus on intricate surface deviations in a tighter FOV.

- Wide-angle cameras provide the “global” context needed to avoid tracking loss on large, featureless geometry.

The result is a hybrid FOV approach: detail stays dense, while acquisition stays stable and efficient.

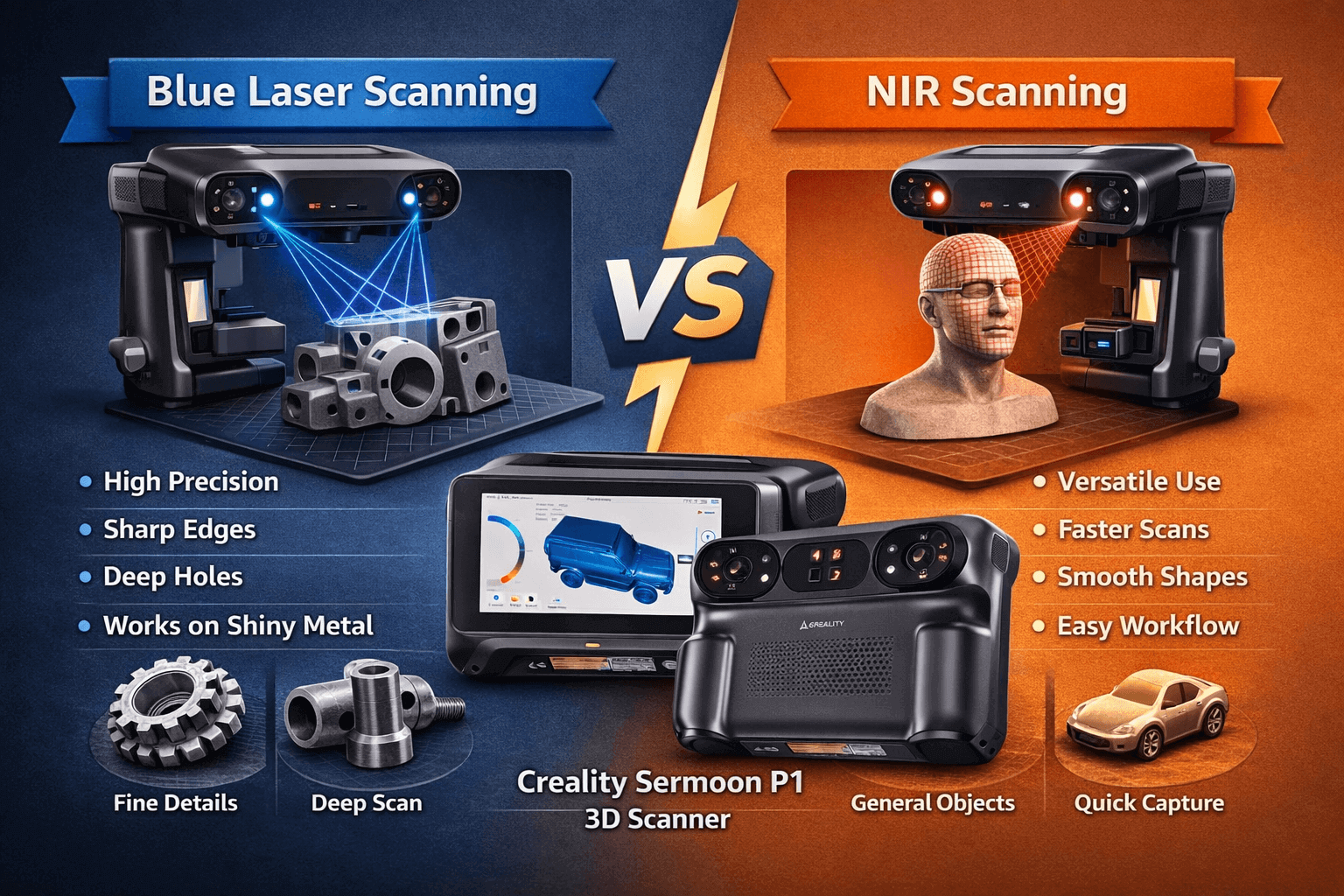

Blue Laser Tri-Mode: 34 vs 7 vs 1 Lines

The P1 uses a blue laser light source. The shorter wavelength reduces diffraction impact and improves absorption/reflection behavior on challenging surfaces like high-gloss metallic finishes and deep-black polymers.

Instead of one fixed laser pattern, the P1 works in three modes:

1) Cross-Line Laser (34 Lines)

Built for maximum volumetric efficiency.

This is the default choice for large objects where rapid coverage is the priority.

2) Parallel-Line Laser (7 Lines)

This is the “detail engine.”

Laser density is concentrated to capture high-frequency textures and complex geometric fluctuations.

3) Single-Line Laser (Deep Feature Specialist)

This targets geometry blind spots.

A single line can reach deep holes, narrow grooves, and recessed internal features that multi-line projections may not penetrate.

Performance Metrics

- Precision: up to 0.02mm

- Volumetric accuracy: 0.02mm + 0.06mm/m

- Point distance: adjustable 0.02mm to 2mm

Infrared Structured Light for Organic Surfaces

Laser-based metrology isn’t always ideal—especially for human subjects or light-sensitive artifacts. The P1 adds a secondary Infrared Mode using structured light for scanning:

- faces

- bodies

- sculptures

The practical advantage here is straightforward: No Marker requirement.

Tracking relies on natural features plus the wide-angle camera array, which reduces setup time.

Combined with the RGB camera, the system supports metrically accurate digital twins by overlaying the geometric mesh with realistic color and texture mapping—useful for cultural heritage and digital entertainment.

Calibration and Stability: What Protects 0.02mm Accuracy

A metrology device is only as trustworthy as its calibration.

Calibration Hardware

The P1 includes a High-Precision Glass Calibration Board. High-borosilicate glass is preferred over plastic or metal in professional metrology because it has a low Coefficient of Thermal Expansion (CTE).

That helps mitigate thermal drift and keeps calibration parameters stable as ambient temperatures change.

Stability and Alignment Controls

Precision metrology is sensitive to mechanical shocks. The P1 requires careful handling because bumps or impacts can cause pixel-shift misalignment between the dual-camera arrays.

Even microscopic optical-axis shifts can compromise 0.02mm precision. If alignment is disrupted, the integrated calibration workflow must be used to restore factory-spec accuracy.

Standalone vs PC Workflows: When Each Mode Wins

This is where the P1’s positioning becomes clear: it shifts from “scanner as a peripheral” to “scanner as a computer.”

An onboard processing unit manages the high-bandwidth stream from the five-camera array.

Standalone Capabilities (On-Device)

- System controls: language selection, network connection (Wi-Fi 6), device protection (passwords)

- 4-step processing: Fusion (frame integration) → Alignment (segment merging) → Meshing (STL/OBJ generation) → Color Mapping

The Practical Split

- Choose Standalone Mode when you want field efficiency: generate a basic mesh immediately and confirm full surface coverage before leaving.

- Choose PC Connection Mode (using CrealityScan 4) when the project requires high-density mesh optimization. Massive projects needing advanced mesh decimation and complex smoothing often benefit from desktop-class processing power and higher thermal envelopes.

Comparative Technical Landscape

The P1 sits in a distinct niche as a Standalone Metrology Workstation—between entry-level sensors and ultra-specialized flagship tools.

Product Hierarchy Comparison

| Axis | Sermoon P1 | CR-Scan Raptor | CR-Scan Otter | Creality RaptorX |

|---|---|---|---|---|

| Technology | Blue Laser & NIR | Blue Laser & NIR | NIR Structured Light | Blue Laser & NIR |

| Laser Modes | 34-Line / 7-Line / 1-Line | 7-Line / NIR | NIR Only | 34-Line / 7-Line / NIR |

| Accuracy | Up to 0.02mm | Up to 0.02mm | Up to 0.02mm | Up to 0.02mm |

| Volumetric Accuracy | 0.02mm + 0.06mm/m | 0.02mm + 0.08mm/m | N/A | 0.02mm + 0.06mm/m |

| Standalone Mode | Yes (Full HD Screen) | No (PC Required) | No (PC Required) | No (PC Required) |

| MSRP (USD) | $2,999 | $1,599 | $959 | $4,599 |

RaptorX remains the flagship for raw speed (34-line mode) and high volumetric accuracy. The Sermoon P1 delivers the same 0.02mm + 0.06mm/m volumetric precision in a standalone form factor for $1,600 less, which positions it as a cost-effective option for professionals who need high accuracy in decentralized environments.

Conclusion: The Frontier of Standalone Metrology

The Sermoon P1 is essentially the convergence of two things:

- high-performance optical engineering (blue laser + infrared structured light)

- autonomous computing (standalone processing + on-device verification)

Final Takeaways

- Hardware synergy: five-camera, dual-light-mode architecture supports both industrial reverse engineering and organic digital twin creation.

- Integrity: high-precision glass calibration and low-CTE substrate choice help keep 0.02mm accuracy stable beyond controlled lab conditions.

- Independence: onboard processing and device protection modernize the 3D data lifecycle with real-time field mesh verification.

As the industry pivots toward standalone metrology, the Sermoon P1 frames a clear benchmark for self-contained, high-precision 3D acquisition.

- ➤【High-Precision Dual-Technology Scanning】-Master any scanning challenge with dual-engine precision. The Sermoon P1 combines Blue Laser and Infrared technologies for maximum versatility. Choose from three professional modes: Deep Hole Scan (Single Line) for cavities, Detail Scan (7 Lines) for complex surfaces, and High-Speed Scan (22 Lines) for large objects. Achieve ultra-detailed 0.02mm accuracy with Blue Laser for mechanical parts, prototypes, and artifacts. Switch safely to Infrared for fast, marker-free scanning of faces, bodies, sculptures, and cultural relics.

- ➤【Flexible Standalone & PC Connected Modes】-Work freely anywhere. Operate completely independently using the built-in 6-inch touchscreen and powerful onboard OS—no computer needed. For advanced projects, connect via USB or Wi-Fi to CrealityScan 4 software on your PC to unlock higher frame rates, enhanced control, and superior processing power for the most demanding tasks.

- ➤【Complete All-in-One Portable Kit】-Ready to scan right out of the box. The package includes: the scanner, high-precision glass calibration board, spare battery, USB 3.0 cable, reflective markers, cleaning cloth, and more. The lightweight handheld design (only 830g) enables effortless 360° scanning of objects ranging from minute details to large-scale volumes.

- ➤【Smart & Simplified Data Processing】-Transform scans into models in just a few steps. Use intuitive built-in tools to seamlessly fuse, align, mesh, and apply color textures directly on the device. For beginners, the “One-Click Process” in CrealityScan 4 software fully automates the workflow—instantly converting raw point clouds into finished, ready-to-use 3D models.

- ➤【Professional Hardware for Unmatched Performance】-Powered by pro-grade specs to handle complex data with ease. Featuring 24GB RAM, 256GB storage, Wi-Fi 7, and a high-speed Qualcomm processor, the Sermoon P1 ensures smooth, uninterrupted operation. Its adaptive laser system supports multiple line patterns (single, parallel, cross) to deliver the optimal balance of detail and speed for every scenario.

FAQ

1) What is the Creality Sermoon P1 positioned as?

A “quasi-industrial” high-precision scanner designed to bridge hobbyist handheld scanners and laboratory-exclusive metrology equipment.

2) Can the Sermoon P1 scan without a PC connection?

Yes. It integrates onboard processing and a high-definition touchscreen for immediate data verification and basic mesh generation without a PC.

3) What are the P1’s blue laser modes?

It uses a tri-mode paradigm: Cross-Line Laser (34 lines), Parallel-Line Laser (7 lines), and Single-Line Laser (deep feature specialist).

4) What is the purpose of 34-line mode?

Maximum volumetric efficiency and rapid coverage, typically for large-scale objects where speed of coverage is the priority.

5) What is 7-line mode used for?

It concentrates laser density as a “detail engine” to capture high-frequency surface textures and complex geometric fluctuations.

6) What is single-line mode used for?

Resolving geometry blind spots: deep holes, narrow grooves, and recessed internal features that multi-line projections cannot penetrate.

7) What accuracy metrics are stated for the Sermoon P1?

Precision up to 0.02mm; volumetric accuracy 0.02mm + 0.06mm/m; adjustable point distance from 0.02mm to 2mm.

8) When should you use Infrared Mode?

When laser-based metrology is suboptimal, such as scanning faces, bodies, sculptures, or light-sensitive artifacts. It supports No Marker scanning and RGB texture mapping for digital twins.

9) What helps the P1 maintain calibration stability?

A High-Precision Glass Calibration Board made from high-borosilicate glass, chosen for low CTE to mitigate thermal drift.

10) When should you use PC Connection Mode?

When a project requires high-density mesh optimization. It uses CrealityScan 4, and desktop-class workstations may be preferred for massive projects needing advanced mesh decimation and complex smoothing.

Leave a Reply