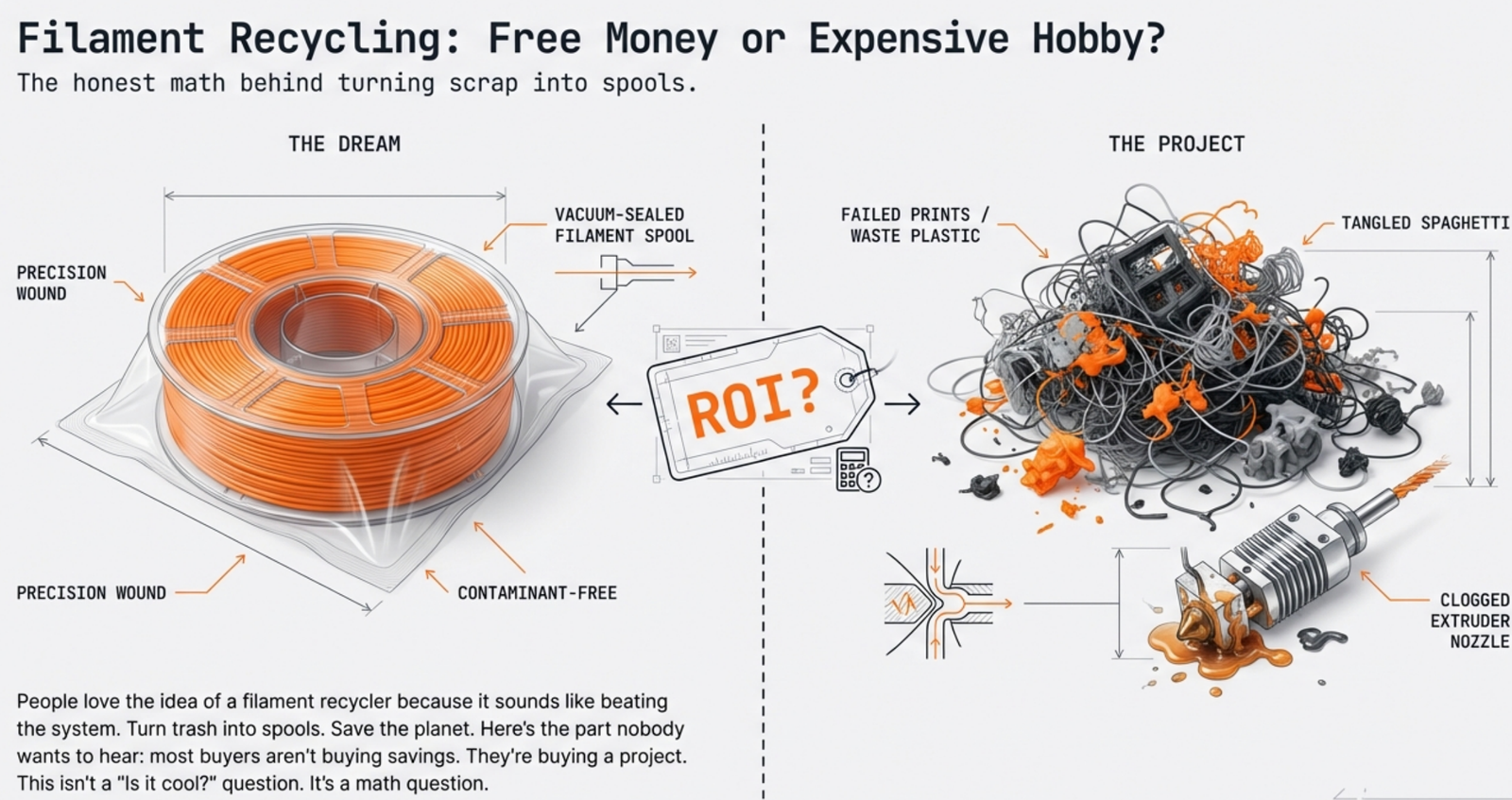

People love the idea of a filament recycler because it sounds like free money. Turn trash into spools. Beat the system. Save the planet. Whatever.

Here’s the part nobody wants to hear: most buyers aren’t buying savings. They’re buying a project. This isn’t a “Is it cool?” question. It’s a math question.

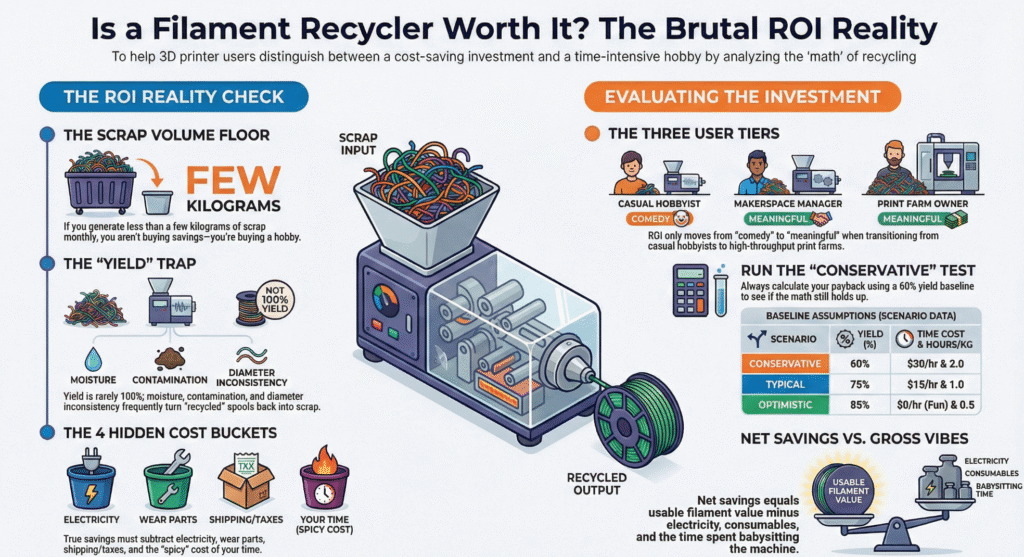

And the math only cares about three inputs: how much scrap you actually have, how often the machine produces usable filament, and how much time you’ll bleed keeping it running.

If you want the fast answer, don’t scroll. Run the numbers.

Quick Verdict

Scrap < X kg/month → you’re not buying savings, you’re buying a new hobby you didn’t ask for.

Payback > 24 months → only worth it if you genuinely enjoy tinkering and maintenance.

Payback < 12 months → worth testing… but don’t confuse “payback” with “smooth experience.”

Table of Contents

The only question that matters: how much scrap do you actually have?

Everyone starts with the wrong number. They start with “filament costs $25/kg, so if I recycle I save $25/kg.”

Nope.

The number that decides everything is boring: How many kilograms of scrap can you reliably feed this thing every month? Not “in theory.” Not “if I start printing more.” Real scrap. Real month.

If your scrap volume is low, the rest of the calculator doesn’t matter. You’ll wait forever to break even because you’re simply not processing enough material to generate meaningful monthly savings.

You can tweak yield. You can pretend your time is free. You can even lie to yourself about electricity. Low scrap still kills ROI.

Quick self-check: which bucket are you in?

Casual printer (low scrap)

You print occasionally. You don’t fail prints often. You don’t generate mountains of support material. Most months, your “scrap pile” is basically vibes.

Regular hobbyist

You print weekly, you tune profiles, you iterate parts, you generate supports, you throw away purge lines, you have a real bin of leftovers.

Farm / heavy user

You’re running machines constantly or producing parts for orders. Scrap is a steady stream, not an occasional accident. This is the only bucket where ROI starts looking less like comedy.

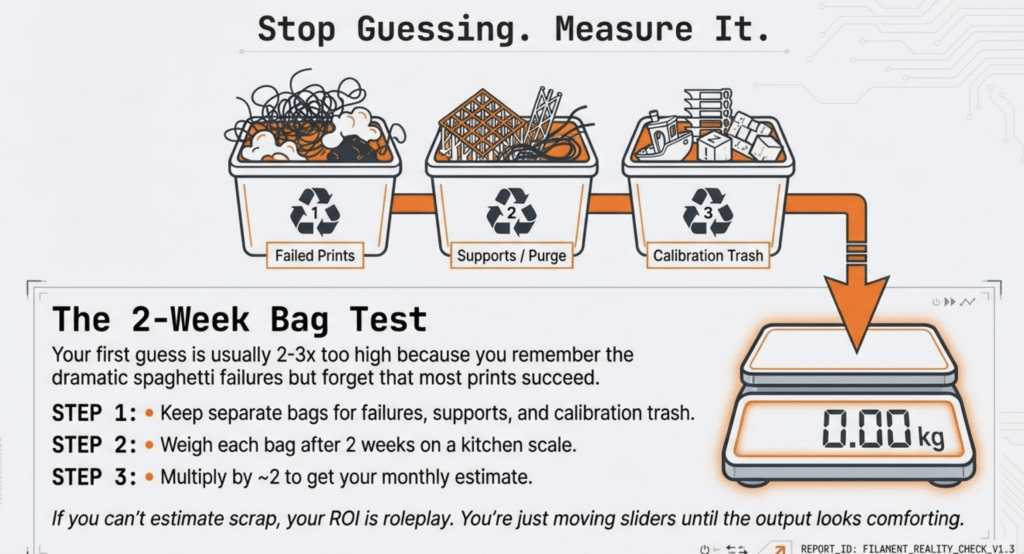

The honest way to estimate monthly scrap

You need a number that isn’t fiction.

Do this for 2 weeks:

- Keep one box/bag for failed prints

- Keep one for supports + brims + purge / prime waste

- Keep one for test prints / calibration trash

- Weigh each bag once a week (cheap kitchen scale works)

- Add it up, then multiply by ~2 to estimate a month

That’s it. Ugly, manual, reliable.

If you want a shortcut and you’ve never weighed scrap in your life, use this rule: your first guess is usually 2–3× too high. People remember the dramatic spaghetti failures. They forget the fact that most prints succeed.

If you can’t estimate scrap, your ROI is automatically fake

If you don’t know your scrap volume, any ROI number you produce is basically roleplay. You’re just moving sliders until the output looks comforting. That’s not analysis. That’s shopping for validation.

So start here. Measure scrap for two weeks. Then use the calculator.

What ROI really means here

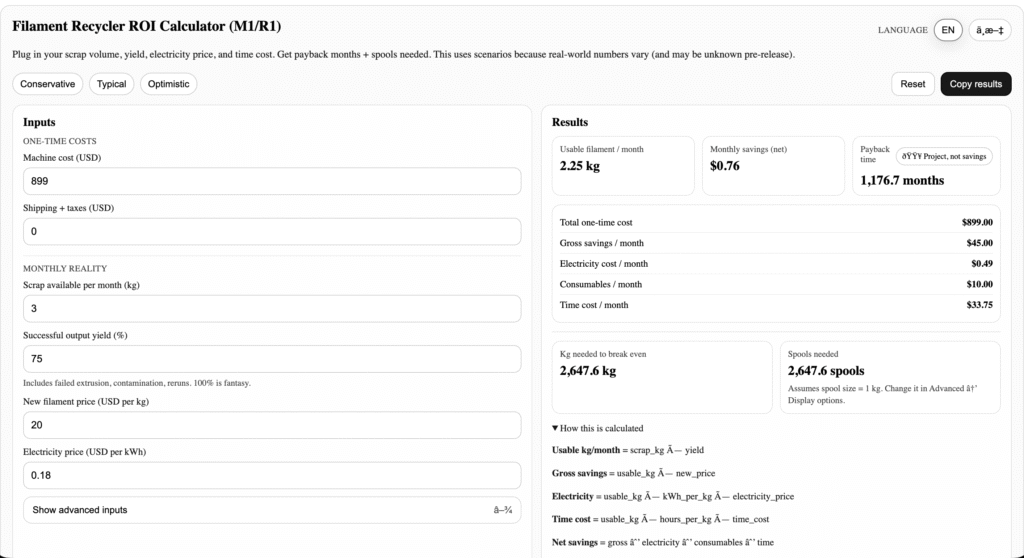

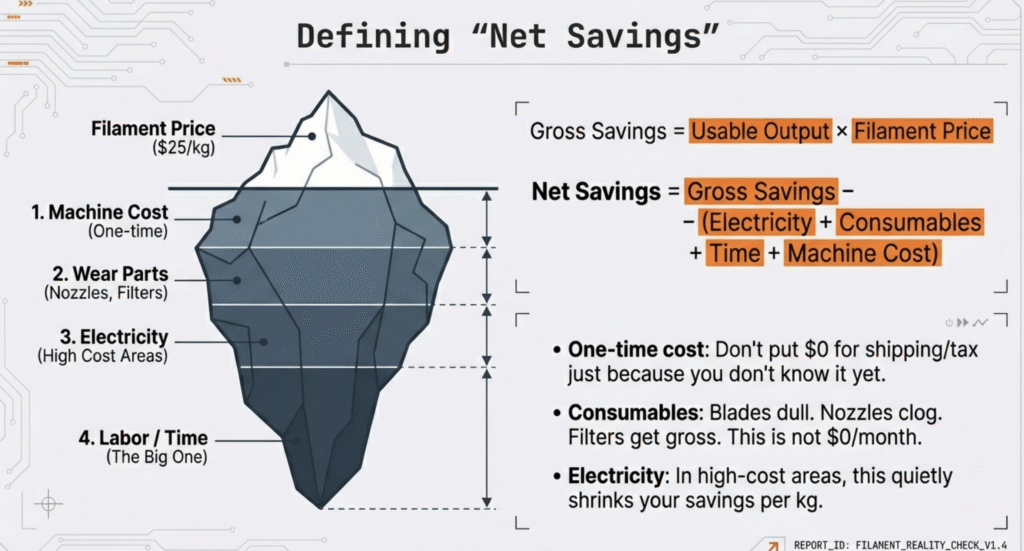

Real ROI is net savings per month, not “filament price.” And net savings only shows up after you subtract the stuff everyone conveniently forgets.

The 4 cost buckets you may ignore:

1) One-time cost (machine + shipping/taxes)

This is the part you want to keep vague because vagueness makes payback look faster.

Don’t. Use the real number you’ll actually pay. If the product is new or pre-release and you don’t know shipping/tax yet, put a conservative placeholder instead of $0. “$0” is how people manufacture a fake ROI.

2) Electricity

Electricity usually won’t destroy ROI by itself… but it’s not zero.

And it matters more in high-cost areas (hello California). If your electricity is expensive, your “savings per kg” quietly shrinks.

3) Consumables / wear parts

Even if the manufacturer doesn’t talk about it, anything that chops, heats, extrudes, and gets fed rough material has wear.

Blades dull. Nozzles clog. Filters get gross. Stuff needs cleaning. Pretending this is $0/month is the second most common ROI lie.

4) Time cost (even if you price it at $0)

This is the spicy one.

If you genuinely enjoy tinkering, you can set your time cost to $0 and still be honest. But you can’t pretend the time doesn’t exist.

This isn’t a magic box that turns random scrap into perfect spools while you sleep. There’s sorting, drying, babysitting, cleanup, and the occasional “why is it doing that?” session.

If you’re buying this to save money, time matters. If you’re buying it as a hobby, time is part of the hobby. Either way, it’s real.

The only 2 outputs that matter

You’ll see a lot of fluff metrics in marketing. Ignore them.

Payback months

This is the blunt answer to “Will this ever cover its own cost?”

Short payback doesn’t mean “easy.” It just means your assumptions aren’t immediately ridiculous.

Spools needed to break even

This one is even better because it forces you to visualize the work.

If the calculator says you need 70 spools to break even, that’s not abstract anymore. That’s:

- 70kg of usable output

- plus whatever scrap and failure rate sits behind that

- plus all the time you’ll spend getting there

If that number makes you sigh, you just got your answer.

“Net savings” is the number you should care about

Here’s the mental model I use:

- Gross savings = usable filament you make × new filament price

- Net savings = gross savings − electricity − consumables − time

Net savings is where truth lives. Everything else is vibes.

If you want to skip the theory and see how brutal the math can be with realistic assumptions, run a conservative scenario first.

The biggest lie: assuming 90–100% yield

Here’s the funny thing about “yield.” People treat it like a footnote. A small percentage you can tweak later.

Wrong. Yield is the whole story.

“Yield” is basically the question: Out of the scrap you feed in, how much becomes filament you’d actually trust enough to print with?

And if you assume 90–100% yield, you’re not being optimistic. You’re writing fan fiction.

What “yield” actually includes

Yield gets destroyed by boring, real-world problems:

- Contamination: mixed plastics, dust, labels, unknown additives

- Moisture: wet material that bubbles, strings, or extrudes unevenly

- Jams and reruns: failed extrusion, inconsistent feed, “start over” batches

- Diameter inconsistency: filament that technically exists but causes print failures

- Rejected output: spools you made… and then realized you don’t want to use

This is why “I can recycle X kg/month” doesn’t mean “I get X kg of usable filament.” You get X × yield. That’s the brutal part.

Three scenarios I actually trust

I don’t like pretending I know your setup. I like giving you guardrails.

Use these three scenarios in the calculator. Start at the bottom, not the top.

- Conservative: You’re learning. Scrap is mixed. You’ll mess up. Some output is trash.

- Typical: You’ve got a routine. Material is mostly consistent. You still lose some batches.

- Optimistic: You’re disciplined. Clean input. Stable workflow. You’re not fighting the machine.

If you start with Optimistic, you’ll get a pretty payback number and buy the machine… then spend months discovering why the “pretty number” wasn’t real.

Default assumptions table

Use this as a starting point. You’re allowed to change it. You’re not allowed to pretend the world is nicer than it is.

| Scenario | Yield (%) | kWh / kg usable | Consumables ($/mo) | Time cost ($/hr) | Hours / kg |

|---|---|---|---|---|---|

| Conservative | 60 | 2.0 | 20 | 30 | 2.0 |

| Typical | 75 | 1.2 | 10 | 15 | 1.0 |

| Optimistic | 85 | 0.8 | 5 | 0 | 0.5 |

Yes, I set “Optimistic” time cost to $0 on purpose. Because that’s the only honest way it happens: you’re doing it for fun, not because your schedule is empty and worthless.

When high yield is plausible

High yield becomes plausible when:

- you recycle one material at a time (not a mystery blend)

- you keep it dry and clean

- you have a repeatable shred/extrude routine

- you’re okay with rejecting output that doesn’t meet your tolerance

It turns into fantasy when:

- your scrap is a random mix of PLA/PETG/“I think this is ABS?”

- you don’t dry anything

- you expect printer-grade consistency from a messy input stream

- you treat every spool as “usable” because it exists

If you want one simple move that instantly makes your ROI honest: run Conservative first. If Conservative looks bad, the purchase is mostly about hobby value. If Conservative looks decent, then you’ve earned the right to try Typical.

Three real-world scenario

This is where people screw up. They read a spec sheet, imagine their best month, and pretend that’s their normal month.

Don’t do that.

Pick the scenario that actually matches your life, then judge the purchase like an adult.

Scenario A — Hobbyist, low scrap

Typical reality

- Scrap: ~0.5–2 kg/month

- Yield: Conservative → Typical range (because mixed leftovers happen)

- Time: you’ll spend more time setting up than producing

How the ROI usually looks

- Net savings is small because usable output is small.

- Payback time often stretches into “why am I doing this?”

The trap

You’ll rationalize it with “But filament is expensive!” while producing maybe one spool every few weeks. The machine sits idle most of the time, so your one-time cost never gets amortized.

If you’re in this bucket, be honest:

Buy it only if you like the process. The “savings” won’t feel like savings.

Scenario B — Regular hobbyist / heavy personal use

Typical reality

- Scrap: ~2–6 kg/month

- Yield: starts Conservative, moves toward Typical as you get disciplined

- Time: you’ll feel the workflow friction, but it’s manageable

How the ROI can flip from “nope” to “maybe”

This is the bucket where yield and time cost actually matter. A small improvement in yield can be the difference between:

- “Never”

- and “okay, 12–18 months”

The trap

Downstream print failures. If your recycled filament has inconsistent diameter or moisture issues, you’ll “save” money on filament… then burn it on failed prints and wasted time.

This is why I keep hammering net savings. Gross savings is easy. Usable, consistent output is the hard part.

Scenario C — Farm / high throughput

Typical reality

- Scrap: 6+ kg/month (and steady)

- Yield: Typical is achievable if input is controlled

- Time: you either systemize it or you suffer

Why the math finally works here

High scrap volume means your monthly usable output is meaningful. Even if you lose some yield, the machine has enough throughput to amortize the upfront cost.

The trap

Workflow becomes the real bottleneck. Sorting, drying, storing, shredding, cleaning—if you don’t treat it like a mini production line, it will eat your schedule alive.

If you’re in this bucket, the question isn’t “Is it worth it?” It’s “Can I build a workflow that doesn’t suck?”

Hidden costs that wreck ROI

Even when the payback math looks decent, the experience can still be miserable.

And the miserable parts are rarely the ones on the product page.

Material sorting & contamination (the silent killer)

If you feed the machine “mystery plastic,” you’ll get mystery filament.

Mixed materials don’t just lower yield. They create filament that behaves unpredictably—warping, weak layers, weird extrusion, clogged nozzles. That’s not “saving money.” That’s paying for frustration.

The uncomfortable truth: the more disciplined you are upstream (sorting), the less pain you suffer downstream (printing).

Drying & storage overhead

Moisture isn’t a minor quality issue. It’s a process tax.

Wet input makes extrusion unstable. Wet filament prints like garbage. The result is you either:

- spend time drying everything, or

- accept lower yield and more rejected output

Either way, ROI takes a hit. Sometimes quietly. Sometimes violently.

Diameter tolerance → downstream failures

You can extrude a spool that looks totally fine, then discover it:

- under-extrudes in random sections

- snaps easily

- jams because the diameter isn’t consistent

Every one of those failures turns your “recycled savings spool” into… another pile of scrap.

This is why yield isn’t just “did it extrude.” Yield is “would I actually trust it on a real print.”

Noise, dust, safety, cleanup time

Shredding and handling scrap isn’t clean. It’s not silent. It’s not cute.

Plastic dust shows up. Bits get everywhere. Blades and hot zones exist. You’ll clean more than you think. If you live in a shared space, this matters.

This part doesn’t show up in the calculator. It shows up in your patience.

Space + workflow friction

The fastest way to hate a machine is to have no home for it.

If you can’t keep:

- scrap bins

- drying setup

- shredder access

- extrusion area

- finished spools

…in a stable workflow, you’ll constantly “set up and tear down,” and that time cost will explode.

This is the moment where a lot of people realize the real price isn’t dollars. It’s friction.

Who should buy this

This kind of machine is either a great fit for your situation or it’s a slow-motion regret generator.

Good fit

You’re a good candidate if most of these are true:

- You generate consistent scrap volume every month (not a random spike once in a while)

- Your scrap is mostly one material (or you’re willing to sort like a grown-up)

- You can tolerate some iteration and maintenance

- You have a place for a semi-permanent workflow (bins, drying, shredding, cleanup)

- You’re okay with the idea that some output will be “good enough,” not perfect

In short: you treat it like a process, not a toy.

Bad fit

You’re a bad candidate if any of these are true:

- Your scrap is low, and you’re hoping the machine will “create savings” out of nothing

- You expect push-button, printer-grade consistency from mixed leftovers

- You don’t want to deal with cleaning, jams, or tuning

- You live in a space where noise/dust/extra bins will immediately annoy you (or someone else)

- Your goal is “saving money,” but your tolerance for friction is basically zero

This is where people buy the dream and then get mad at reality.

The “I still want it” checklist

Before you buy, answer these five questions without flinching:

- How many kg of scrap do I really have per month?

- Am I willing to sort by material (or accept lower yield)?

- Where will this workflow live permanently?

- How much inconsistency can I tolerate in prints made from recycled filament?

- Am I buying savings… or am I buying a project I actually want?

If you can answer those cleanly, you’re already ahead of most buyers.

If you can’t, stop scrolling and run Conservative in the calculator. It’ll tell you what your brain is trying to avoid.

How to use the calculator without fooling yourself

The calculator isn’t the hard part. The hard part is not using it like a slot machine until it spits out a number you like.

Here’s the method that keeps you honest.

The 4-step method

1) Fill Basic fields only

Machine cost, shipping/tax, scrap kg/month, yield, filament price, electricity price.

Stop. Don’t touch advanced yet.

2) Run Conservative

This is your “truth baseline.” If Conservative looks ugly, that’s not the calculator being negative. That’s your assumptions being realistic.

3) Change one variable at a time

Most people ruin the math here. They tweak yield, scrap volume, filament price, time cost, and consumables all at once. That’s not analysis. That’s story-writing.

Pick one input. Adjust it. Re-run. Keep the rest fixed.

4) Decide using the verdict badge (✅ / 🟨 / 🟥)

That badge is basically your adult supervision:

- ✅ means the math could work (not guaranteed, but plausible)

- 🟨 means “this better be fun, because it’s not fast money”

- 🟥 means “you’re buying a project, not savings”

If you get “Never (net ≤ 0)”: what to adjust

This is where people do the worst cheating.

Adjust these

- Scrap kg/month: if you measured wrong or your volume is actually higher

- Yield: if you can improve input purity and workflow

- Time cost / hours per kg: if you genuinely treat it as hobby time, or you streamline the process

Don’t adjust these just to feel better

- Shipping + taxes = $0 because you don’t know yet (No. Put a placeholder. Unknown doesn’t mean free.)

- Filament price using the most expensive boutique spool you’ve ever seen (Use what you actually buy.)

- Consumables = $0 because you don’t want to think about wear (Stuff wears. Period.)

If the only way to make the result “work” is to pretend nothing costs anything and everything runs perfectly, the answer isn’t “buy it.” The answer is “you want it for fun.” Which is fine. Just call it what it is.

FAQ

1) What scrap volume makes this worth considering?

If you’re under X kg/month, you’re fighting an uphill battle. Low volume makes payback crawl because you’re not producing enough usable filament per month to generate meaningful net savings.

If you don’t know your X yet, run Conservative with your measured scrap number. That will tell you whether you’re in “maybe” territory or “why are we doing this” territory.

2) How do I estimate yield if I’ve never used a recycler?

Start Conservative. Seriously.

If you haven’t run a recycler before, you don’t have the muscle memory for sorting, drying, and troubleshooting. Conservative is the only assumption that doesn’t lie.

3) Does electricity cost matter in real life?

It usually doesn’t destroy ROI, but it does shave it. Especially in high-rate areas. It’s one of those “death by a thousand cuts” costs when combined with consumables and time.

4) Should I include time cost, or set it to $0?

If you’re buying this to save money, include time.

If you’re buying this because you enjoy tinkering, set it to $0—but don’t pretend you won’t spend hours.

5) What filament price should I use in the calculator?

Use what you actually buy most often. Not the cheapest spool you could find once. Not the most expensive spool you wish you bought. Your real average.

6) Is this mainly a PLA thing, or does PETG/ABS/TPU work too?

The broader your material mix, the harder everything gets: sorting, consistency, print predictability. If you want the highest chance of decent yield, keep your input material controlled instead of mixing a soup.

7) How many spools do I need to recycle to break even?

That’s exactly why the calculator outputs spools needed. It converts the financial question into a workload question. If the spools number feels insane, that feeling is your answer.

8) Why do most home filament recyclers fail to pay back?

Because people overestimate scrap volume, assume high yield, ignore time cost, and treat every spool that exists as “usable.” Reality hits, yield drops, time climbs, and net savings evaporates.

9) What assumptions make ROI look unrealistically good?

- Yield near 100%

- Shipping/tax set to $0

- Consumables set to $0

- Time cost ignored while also claiming it’s a “money saver”

- Using an inflated filament price you don’t actually pay

10) What should Creality publish for this to be trustworthy (before you buy)?

Not marketing adjectives. Data:

- Measured energy use per kg

- Measured yield under defined input conditions

- Consumables / wear part expectations

- Output tolerance (diameter consistency) and real-world print validation

If they publish that transparently, it’s a good sign they’re not selling pure vibes.

Closing: Payback isn’t the same as “worth it”

If your calculator result says “payback in 10–12 months,” that’s not a guarantee. It just means the math doesn’t immediately collapse under realistic assumptions.

You’re still buying a workflow. Sorting. Drying. Cleaning. The occasional jam. The batch you don’t trust enough to run on a long print.

So here’s the honest framing:

- If the process sounds fun, ROI is a bonus.

- If the process sounds annoying, ROI better be outstanding… and even then, you might still hate it.

Run Conservative. If it still looks decent, you’ve earned the right to take this seriously.

Don’t buy “savings.” Buy the workload you can actually live with.

Leave a Reply